The art of growing artificial gemstones is a captivating fusion of science, precision, and craftsmanship. These lab-grown gems offer a sustainable and cost-effective alternative to their natural counterparts, but the journey from mineral seeds to stunning gemstones is not without its challenges.

In this comprehensive guide, we will delve into the challenges faced during the growth process of artificial gemstones and the innovative strategies employed to overcome them.

Chapter 1: The Complex World of Crystal Growth

Understanding the Growth Process

To embark on a journey through the intricate landscape of artificial gem growth, it is essential to first grasp the fundamentals of the crystal growth process. The creation of synthetic gemstones is a remarkable fusion of science and art, where controlled conditions and meticulous techniques give rise to stunning gems that rival their natural counterparts. In this chapter, we will provide a brief yet comprehensive overview of how these mesmerizing creations come into existence.

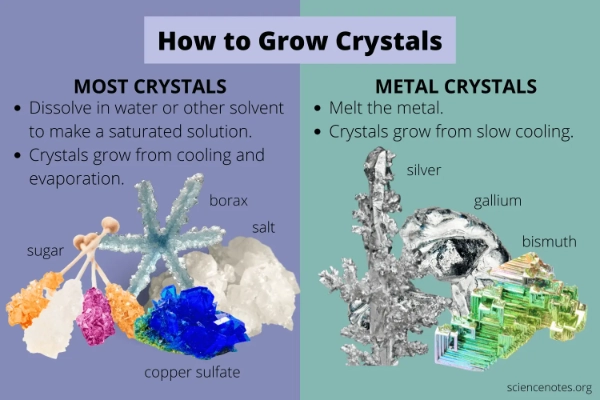

The Birth of Crystals: At the heart of the process lies the transformation of raw materials into structured, crystalline beauty. This transformation involves the careful selection of base materials, the application of heat, pressure, and other factors to mimic the conditions found in nature, and the nurturing of crystal growth over time. Understanding the steps involved in this journey is the key to appreciating the challenges that gem growers face.

The Role of Chemistry and Physics: The growth of artificial gemstones is not merely a matter of chance; it is a science grounded in chemistry and physics. Precise control over factors such as temperature, pressure, and chemical composition is essential to steer the growth process in the desired direction. The interplay of these elements forms the basis for crafting gemstones of exceptional quality and beauty.

Chapter 2: Challenges in Controlling Crystal Quality

Maintaining Consistency

As we delve deeper into the world of artificial gem growth, we encounter the complex challenge of maintaining consistency in the crystal growth process. Consistency is the hallmark of high-quality gemstones, ensuring that each gem possesses the desired characteristics and meets the stringent standards set by gem enthusiasts and the jewelry industry.

The Quest for Uniformity: Achieving uniformity in crystal growth is a formidable task. It involves not only replicating the growth conditions precisely but also addressing subtle variations that can arise during the process. Even minor deviations can result in inconsistencies in gemstone size, color, or clarity. Overcoming these challenges requires a combination of cutting-edge technology and meticulous craftsmanship.

Controlling Impurities

Impurities represent another significant challenge in the pursuit of flawless artificial gemstones. Impurities can have a profound impact on a gem’s clarity, color, and overall quality. To produce gems that rival their natural counterparts, gem growers must implement sophisticated techniques to minimize the presence of impurities during the growth process.

The Impurity Conundrum: Impurities can enter the crystal lattice during growth, leading to undesirable effects such as cloudiness or unwanted coloration. Addressing this conundrum involves carefully selecting raw materials, optimizing growth conditions, and implementing purification methods to ensure that the final gemstones are free from imperfections.

Chapter 3: Navigating Temperature and Pressure

High-Temperature Growth

The art of growing gemstones often involves subjecting raw materials to extreme temperatures. This chapter delves into the challenges and ingenious solutions associated with creating the ideal high-temperature conditions required for the growth of exquisite synthetic gemstones.

The Heat of Creation: High-temperature growth is a critical component of the gemstone cultivation process. Mimicking the intense heat found deep within the Earth’s crust, gem growers subject their materials to temperatures that can range from scorching to sizzling. These elevated temperatures create the perfect environment for crystals to form and flourish. However, mastering this fiery domain presents its own set of challenges.

Challenges at the Furnace: Operating at high temperatures is no simple feat. Equipment must be designed to withstand extreme heat, and precise temperature control is essential to ensure the desired crystalline structures are achieved. The management of thermal gradients and the prevention of material loss due to excessive heat are among the key challenges that gemstone growers face in the pursuit of perfection.

High-Pressure Challenges

In the world of gemstone growth, high-pressure environments are a necessity. This section illuminates the complexities of maintaining stable pressure conditions during the gem cultivation process and the innovative approaches taken to tackle these challenges.

Pressing Matters: High-pressure growth conditions are essential for the creation of gems with remarkable clarity and structural integrity. However, maintaining these conditions can be demanding. Ensuring that pressure remains stable throughout the growth process is a meticulous and technologically advanced endeavor.

Precision Under Pressure: Gem growers must navigate the intricacies of high-pressure chambers and equipment to create the perfect conditions for gem growth. The challenge lies in achieving uniform pressure gradients, preventing leaks, and managing the safety aspects of operating under such extreme conditions. With the right expertise and cutting-edge technology, these challenges are transformed into opportunities for creating gems of unparalleled quality.

Chapter 4: The Art of Precision Cutting

Precision Cutting Techniques

Once gemstones have completed their growth journey, they require the deft touch of master craftsmen to bring out their full potential. This chapter explores the delicate art of precision cutting, the challenges it presents, and the tools and skills needed to achieve perfection.

Crafting Gem Masterpieces: Precision cutting is the craft of transforming rough gemstones into dazzling works of art. It involves shaping gemstones with meticulous precision to reveal their inner beauty. The skillful hands of gem cutters wield precision instruments to create facets, angles, and dimensions that maximize a gem’s brilliance.

Challenges in the Cutter’s Workshop: Gemstone cutting is a labor-intensive process that demands unwavering attention to detail. Challenges arise in achieving the desired proportions, symmetry, and facet alignment. Gem cutters must also make calculated decisions to balance the preservation of carat weight with the realization of the gem’s optical potential.

Minimizing Material Loss

The precision cutting of gemstones is not without its trade-offs. Material loss can occur during the cutting process, affecting both the gem’s size and value. This section explores strategies employed to minimize waste and maximize the yield of cut gemstones.

Balancing Act: Gem cutters walk a fine line between preserving the maximum carat weight and optimizing a gem’s optical properties. Achieving this balance is a complex task that requires experience and a deep understanding of the gem’s characteristics.

The Art of Yield Maximization: Techniques such as computer-aided design (CAD) and meticulous planning are used to minimize material loss during the cutting process. These approaches ensure that every facet cut brings out the gem’s inner radiance while preserving its value.

Chapter 5: Ensuring Optimal Optical Properties

Achieving Optical Perfection

The world of gemstones is intrinsically linked to their optical properties, which define their beauty and allure. This chapter delves into the methods employed to optimize these properties, including refractive index and dispersion, to ensure gemstone quality.

The Play of Light: Gemstones are renowned for their ability to capture and reflect light in mesmerizing ways. Achieving optimal optical properties is a fundamental goal of gem cultivation. This involves controlling factors like refractive index, which determines a gem’s brilliance, and dispersion, responsible for its fire and spectral colors.

Mastery of Refractive Index: The refractive index of a gemstone is a critical factor that affects its brilliance. Gem growers employ various techniques to ensure that the refractive index aligns with the desired specifications for the gem, maximizing its ability to refract and reflect light.

Addressing Color Enhancement

Color is a defining characteristic of gemstones, and enhancing or altering it can be a delicate art. This section delves into the challenges and innovative solutions in the realm of color enhancement techniques employed to improve a gem’s appearance.

Enhancing Natural Beauty: While many gemstones exhibit stunning natural colors, others may benefit from color enhancement to achieve a more desirable hue. These enhancements require a deep understanding of the gem’s chemistry and the application of controlled treatments.

Challenges in Chromatic Mastery: Addressing color enhancement challenges involves striking a balance between achieving the desired color and preserving the gem’s overall integrity. Gem growers must navigate the complexities of chemical treatments and advanced technologies to produce gems with enhanced, yet natural-looking, colors.

In this exploration of the intricacies of temperature, pressure, precision cutting, and optical perfection, we gain a deeper appreciation for the dedication and expertise that go into creating the mesmerizing world of synthetic gemstones. These chapters reveal the challenges and triumphs of gem growers, from the fiery crucibles of high-temperature growth to the meticulous precision of gemstone cutting, all in pursuit of crafting gemstones that captivate our hearts and eyes.

Conclusion

In conclusion, the process of growing artificial gemstones presents a myriad of challenges, from maintaining crystal quality to navigating extreme temperature and pressure conditions. However, it is the relentless pursuit of innovation and the application of scientific principles that enable gemstone growers to overcome these obstacles and produce exquisite lab-grown gems that rival natural ones.

Frequently Asked Questions (FAQs)

- Q1: Are artificial gemstones considered real gemstones? A1: Yes, artificial gemstones are real gemstones. They have the same physical and chemical properties as natural gems but are created in a controlled laboratory environment.

- Q2: Are there ethical concerns surrounding the growth of artificial gemstones? A2: Artificial gemstone production is generally considered more ethical than certain aspects of natural gem mining, as it reduces environmental impact and avoids issues like “blood diamonds.”

- Q3: Can artificial gemstones be used in engagement rings and fine jewelry? A3: Absolutely! Many people choose artificial gemstones for engagement rings and fine jewelry due to their quality, affordability, and ethical considerations.

- Q4: What are the most common types of artificial gemstones? A4: Some of the most common types include lab-grown diamonds, sapphires, rubies, and emeralds.

- Q5: How do artificial gemstones compare to natural ones in terms of value? A5: The value of artificial gemstones varies depending on factors like quality and market demand. While they are typically more affordable than natural gems, their value can still be substantial.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article