Introduction

High-power lasers are critical in a variety of sectors. The backbone of these lasers is the crystalline material chosen. Here, we provide a comprehensive look into the materials that shape the world of high-power lasers.

Understanding Lasers Crystals

Laser crystals are the medium in solid-state lasers, amplifying light through stimulated emission. The selection of these materials can greatly influence a laser system’s performance, efficiency, and durability.

Nd:YAG vs. Yb:YAG

The debate between the usage of Nd:YAG and Yb:YAG crystals in high-power lasers is often the center of discussion among experts. Both materials have established their position in the industry, but they cater to varying needs and applications, making the choice contingent upon the specifics of the desired output and functionality.

Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) stands out as a hallmark in the realm of laser crystals. Its recognition is well-deserved, considering the impressive traits it brings to the table. Its strong thermal and mechanical stability ensures that the crystal remains undistorted, even under demanding conditions. This stability factor plays a pivotal role when continuous wave and pulsed operations are in play. Lasers require a medium that can handle abrupt changes, and Nd:YAG rises to the occasion with its high gain and low threshold attributes. However, it isn’t without its limitations. The crystal’s tuning range, for instance, is relatively narrow. Moreover, users must be cautious of the potential for thermal lensing, which, if unchecked, could affect the laser’s performance.

On the flip side, Yb:YAG (Ytterbium-doped Yttrium Aluminum Garnet) is carving a niche for itself, especially in the sphere of diode-pumped lasers. One of its standout features is the broad absorption bands, which align perfectly with diode pumping, allowing for more efficient energy transfer. Another significant advantage is its reduced vulnerability to thermal effects, making it an attractive choice for applications that might be sensitive to heat-related inconsistencies. However, nothing is without trade-offs. The Yb:YAG crystal’s upper-level lifetime doesn’t quite measure up to that of Nd:YAG. Additionally, the cost associated with Yb:YAG can be a deterrent for some, as it generally tends to be more expensive.

In conclusion, the choice between Nd:YAG and Yb:YAG isn’t black and white. It’s essential to weigh the advantages against the limitations, taking into consideration the specific needs of the application in question. Both crystals have their unique strengths, and understanding them is key to optimizing their potential.

Exploring Nd:Glass

The world of high-power lasers continually evolves, and at the forefront of innovation lies materials like Nd:Glass. This remarkable material, a phosphate glass laced with neodymium ions, offers a unique set of characteristics that make it a favorite, especially in pulsed laser systems.

Diving into the advantageous facets of Nd:Glass, one cannot ignore its broad bandwidth. This feature is particularly beneficial for high-energy, short-pulse lasers, as it allows for a broader range of frequencies to be produced without the need for extensive tuning or adjustments. The broad bandwidth of Nd:Glass ensures that lasers can emit intense, focused pulses in quick successions, a necessity in many advanced applications.

Furthermore, another standout trait of Nd:Glass is the ability to tailor its performance through its composition. By adjusting the concentrations and combinations of its ingredients, manufacturers can fine-tune the glass’s properties to align perfectly with specific requirements. This malleability in performance is seldom found in other laser materials, making Nd:Glass a preferred choice for researchers and industries seeking customization.

However, like all materials, Nd:Glass has its set of challenges. One primary concern is its thermal conductivity, which is relatively lower than most crystalline materials used in lasers. This reduced conductivity means that Nd:Glass isn’t as efficient in dissipating heat. In high-power applications, where heat generation is significant, this can pose challenges in maintaining the system’s stability and performance.

Another point of contention is the material’s vulnerability to thermal shock. Rapid temperature changes can potentially damage the glass, leading to cracks or other structural issues. This sensitivity mandates that systems employing Nd:Glass need to have efficient cooling mechanisms in place to ensure longevity and consistent performance.

In essence, while Nd:Glass offers a plethora of benefits, especially in the domain of pulsed lasers, it comes with its set of limitations. Recognizing and navigating these challenges is crucial for leveraging its full potential in high-power laser applications.

A Look at Other Prominent Crystals

In the intricate landscape of high-power lasers, while the likes of Nd:YAG, Yb:YAG, and Nd:Glass command significant attention, there exists an array of other crystals that have etched their mark in various capacities. These materials, with their distinct attributes, bring a fresh dimension to the vast realm of laser applications.

Ruby, scientifically known as Chromium-doped Aluminum Oxide (Cr:Al₂O₃), holds a special place in the history of lasers. Often celebrated for its pioneering role, Ruby was the very medium used in the creation of the first-ever laser in 1960. Its radiant red fluorescence isn’t just captivating to the eye but also serves a functional purpose. The chromium ions in the Ruby crystal offer sharp emission lines in the red part of the spectrum, which made it an initial favorite for many laser applications. While Ruby lasers have since been overshadowed by newer technologies in many areas, their historical significance remains undiminished.

On the more contemporary front, Titanium-doped Sapphire, commonly referred to as Ti:Sapphire, has emerged as a game-changer. This crystal’s standout feature is its ability to support ultrafast laser operations. Ti:Sapphire lasers have been instrumental in producing incredibly short and intense pulses, sometimes just a few femtoseconds in duration! This capability has opened new horizons in areas like spectroscopy, microscopy, and even in fundamental research in physics where understanding phenomena at ultra-short timescales is essential.

Additionally, what sets Ti:Sapphire apart is its wide tuning range, making it versatile for various applications. The crystal’s broadband capability, coupled with its high damage threshold, positions it at the forefront of modern laser research and application.

In summation, the world of laser crystals is both diverse and dynamic. While certain materials like Nd:YAG and Nd:Glass have established themselves as mainstays, others, from the historic Ruby to the cutting-edge Ti:Sapphire, play crucial roles in shaping the past, present, and future of laser technology. Each crystal, with its unique properties, contributes to the broader narrative of innovation and advancement in the laser domain.

Crystal Selection Factors

Navigating the intricate world of laser crystals necessitates a comprehensive understanding of the myriad factors that determine the best fit for specific applications. The selection isn’t a one-size-fits-all; rather, it’s a meticulous process where each parameter plays a decisive role in the final outcome.

First and foremost, the desired wavelength of the emitted light stands tall among considerations. This is the specific color or frequency of light that the laser produces, and it needs to be in perfect harmony with the intended application. For instance, medical lasers targeting hemoglobin, a molecule in blood, will require a different wavelength than lasers designed for industrial cutting or engraving. The crystal’s natural emission properties, therefore, become a defining criterion. One must ensure that the chosen crystal can generate light at the exact wavelength required for optimal performance and efficiency.

Thermal management is another paramount aspect. Lasers, especially those operating at high powers, can produce significant amounts of heat. The way a crystal handles this heat can profoundly impact the laser’s operation. Factors like thermal conductivity, resistance to thermal shock, and tendencies towards thermal lensing become critical. For high-powered operations where heat generation is intense, crystals with superior thermal attributes are non-negotiable. This ensures longevity, stability, and consistent performance, all while avoiding potential damages from overheating.

Lastly, the pulse duration is a defining factor, especially in applications where ultra-precise, short bursts of energy are crucial. In scenarios like these, broad bandwidth materials come into the spotlight. Crystals like Nd:Glass, with their ability to support shorter pulses, become the go-to choice. Their inherent properties allow for the generation of swift and intense pulses, making them invaluable in applications ranging from medical surgeries to advanced research methodologies.

To encapsulate, the realm of laser crystals is nuanced, with each material offering a unique blend of advantages. Making an informed choice requires a keen understanding of the desired output and the inherent properties of the available crystals. Through a blend of science, research, and technology, one can pinpoint the perfect crystal to fulfill specific laser needs.

Conclusion

The choice of crystal material is pivotal for the efficiency and functionality of high-power lasers. Materials such as Nd:YAG, Yb:YAG, and Nd:Glass each offer unique advantages. As technology progresses, so does the quest for superior laser materials.

FAQs

- 1. How do laser crystal materials differ?

Each crystal has unique thermal properties, damage thresholds, and emission wavelengths. - 2. Are there emerging materials in the laser industry?

Yes, with technological advancements, new materials are continually explored for their potential. - 3. How does the doping process affect lasers?

Doping elements like neodymium or ytterbium influence the laser’s emission wavelength and overall efficiency. - 4. What’s the significance of thermal management in lasers?

To prevent distortion or damage, it’s essential to manage the heat generated by high-power lasers effectively. - 5. Can one laser crystal cater to all needs?

No, different applications have specific requirements, so the choice of material needs to align with the purpose.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

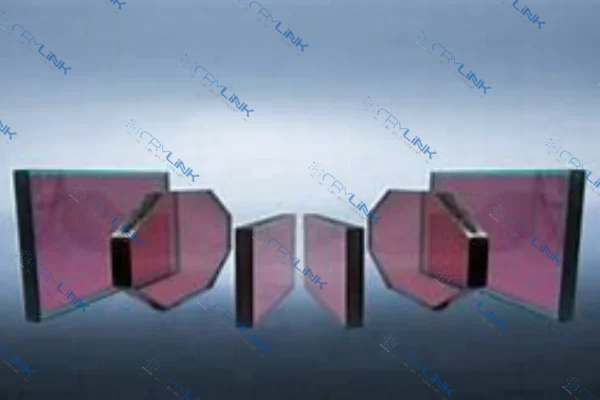

Related Product(s) with this Article

Related Application(s) with this Article