The main attraction of erbium glass lasers lies in their wavelength range (approximately 1.53–1.56 µm), which offers eye safety. For the naked eye, the maximum permissible exposure (MPE) for 1.54 µm laser radiation is five orders of magnitude higher than that of the 1.06 µm neodymium laser, making it much safer for medical applications. Additionally, the 1.54 µm wavelength of erbium glass lasers aligns closely with the minimum loss spectrum in silicon waveguides, offering a unique advantage for applications outside of fiber configurations.

Although the 1.54 µm wavelength laser has obvious eye safety advantages, erbium glass typically has lower efficiency, requiring the use of sensitizers to enhance its performance. To improve the efficiency of erbium glass, Yb³⁺ (yttrium ion) is typically added as a sensitizer. Yb³⁺ ions absorb near-infrared (900–1000 nm) pump radiation provided by flash lamps or laser diodes (LDs), transferring energy to Er³⁺ ions, thereby increasing the output power of er glass lasers.

1. Working Principle and Sensitization Process of Erbium Glass

1.1 Working Principle and Wavelength:

The laser emission wavelength of erbium glass is typically 1.54 µm, resulting from the 4I13/2–4I15/2 transition of Er³⁺ ions. This wavelength has excellent eye safety because liquid water has a high extinction coefficient at around 1.5 µm, which prevents the laser from reaching the retina and reduces the risk of retinal damage. Erbium glass is typically made from phosphate glass or other types of glass materials. Erbium ions, through their specific energy level structure, can absorb energy from external pump sources and release laser photons through radiative transitions.

1.2 Sensitization Process:

A key characteristic of erbium glass is that erbium ions themselves have relatively weak absorption capabilities, so sensitizers are added to improve laser efficiency. The most commonly used sensitizer is the yttrium ion (Yb³⁺). Yb³⁺ ions absorb near-infrared pump light (900–1000 nm) and transfer energy to Er³⁺ ions, exciting them to higher energy levels. This process is called sensitization. Through this sensitization process, erbium glass lasers can achieve higher energy conversion efficiency with relatively low pump power.

1.3 Pump Sources:

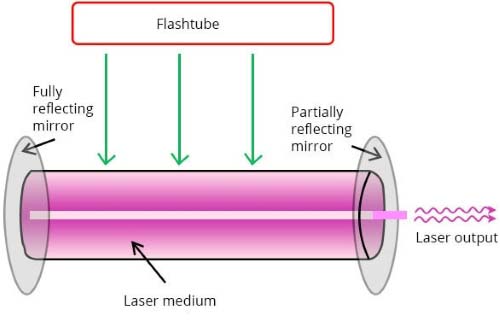

Erbium glass typically uses flash lamps or laser diodes (LDs) to provide energy. Flash lamp pumping is a traditional method that provides high-energy short pulses to excite the gain medium. Laser diode pumping has become a widely used method in recent years, emitting near-infrared light (900–1000 nm) to directly excite Yb³⁺ ions. The advantage of laser diode pumping is that it can provide a stable and efficient pump light source, making it particularly suitable for applications requiring high power and continuous-wave (CW) laser output.

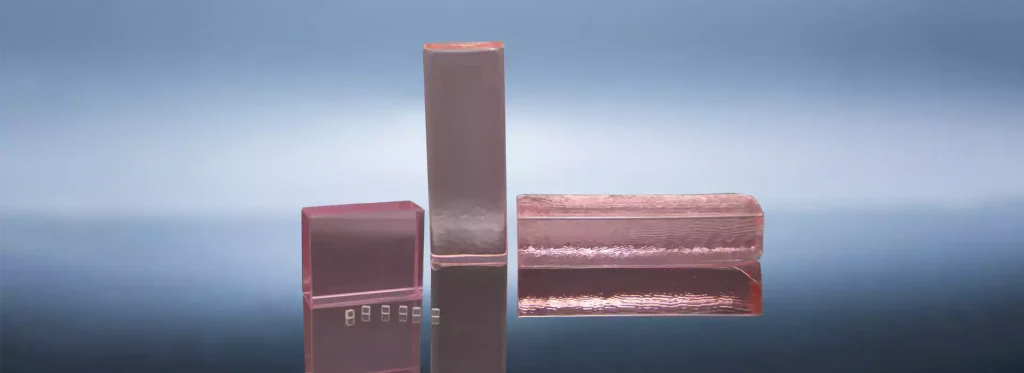

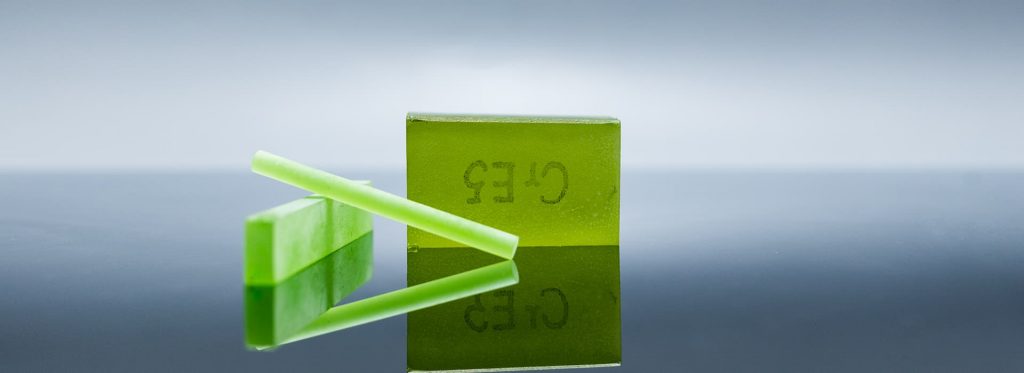

1.4 Phosphate Glass and Other Matrix Selections:

While erbium-doped glass can serve as a gain medium, the type of glass matrix used has a significant impact on the performance of erbium glass lasers. Phosphate glass is widely regarded as one of the best matrices for Yb–Er glass lasers. The unique advantage of phosphate glass is that it can effectively combine the long-lived 4I13/2 laser level (about 7 ms) and the short-lived 4I11/2 level (about 2–3 ms), which helps improve laser efficiency. Additionally, phosphate glass has resonance with the excited state 2F5/2 of Yb³⁺, further enhancing energy transfer efficiency.

2. Pumping mode

2.1 Flash Lamp Pumping

Flash lamp-pumped erbium glass lasers are one of the most traditional designs. In certain high-energy-demand situations, flash lamp pumping remains an effective and economical choice. Flash lamp-pumped erbium glass lasers can output high-energy pulses in free-running mode, with pulse energy reaching several tens of joules, and in Q-switched mode, output energy can reach several joules.

The working principle of flash lamp-pumped erbium glass lasers is to use the high-energy short pulses emitted by the flash lamp to excite Yb³⁺ ions in the Yb–Er glass, transferring energy to Er³⁺ ions and exciting them to the laser energy level, generating 1.54 µm laser radiation.

One advantage of flash lamp pumping is that it can provide a large pump energy, particularly for applications that require high-power pulsed outputs. The efficiency of flash lamp-pumped Cr–Yb–Er glass is typically 2–4 times higher than that of non-chromium (Yb–Er and Nd–Yb–Er) glasses. However, Cr–Yb glass lasers with higher chromium content suffer from more heat dissipation and are more prone to thermal cracking, resulting in about 1.5 times lower average power than non-chromium glass lasers.

Challenges and Solutions:

However, the efficiency of flash lamp-pumped erbium glass lasers is limited by the low thermal conductivity of the glass, which causes it to crack due to heat accumulation. To improve performance, many flash lamp-pumped erbium glass lasers incorporate thermal management measures, such as using deuterium oxide (D₂O) as a cooling liquid or designing narrower pump chamber gaps to reduce light absorption by water layers, thus improving thermal management and laser efficiency.

2.2 Laser Diode (LD) Pumping

In recent years, laser diode (LD) pumping has become one of the most common pumping methods for erbium glass lasers. LD-pumped erbium glass lasers can be divided into two configurations: transverse pumping and longitudinal pumping.

Transverse Pumping:

In this configuration, an array of laser diodes pumps the glass laser rod from both sides. Typically, transverse-pumped lasers operate in pulsed mode, with pulse durations on the order of milliseconds. To achieve higher pump power, multiple LD arrays or stacks are often used, rather than a single LD.

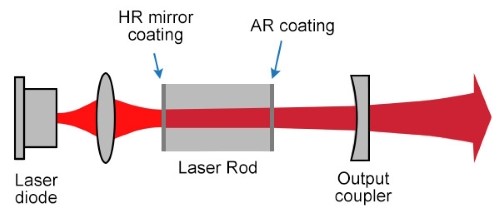

Longitudinal Pumping:

Longitudinal-pumped lasers are typically designed as more compact, miniature lasers. They use one or a few laser diodes to provide the pump light, and the pump region has a smaller diameter, suitable for achieving a lower threshold and supporting continuous-wave (CW) mode operation.

A typical advantage of longitudinal pumping is its miniaturization and high efficiency. For example, micro-scale longitudinal-pumped lasers using Yb–Er glass with high yttrium concentrations can achieve significant performance. This design enables the micro-lasers to have a lower pump threshold and operate stably in CW mode.

3. Erbium Glass Applications

Eye-Safe Laser:

The specific wavelength (1.5 µm) produced by Er:Glass coincides with a strong absorption peak in water. Since the human cornea and lens contain high water content, they absorb the laser radiation effectively, reducing the amount of light transmitted to the retina. The retina, which is the light-sensitive layer of the eye, is especially susceptible to damage from high-power lasers. Therefore, compared to lasers that reach the retina, Er:Glass lasers are classified as relatively safe for the human eye.

Lidar Ranging:

In addition to eye safety, the 1.5 µm wavelength of Er:Glass lasers is ideal for laser ranging devices. It exhibits good transparency in the atmosphere, allowing the light beam to travel long distances with minimal attenuation. This wavelength also aligns with the peak sensitivity of certain infrared photodetectors that work at room temperature, including indium gallium arsenide (InGaAs) and germanium (Ge) photodiodes.

Medical and Aesthetic Applications:

Erbium glass lasers are used for non-ablative laser skin resurfacing. The 1540 nm wavelength is highly absorbed by water molecules in the skin tissue. Non-ablative lasers use this wavelength to heat the tissue in a controlled manner, stimulating collagen production, which improves the appearance of fine lines, wrinkles, and uneven skin tone without removing the skin’s surface. Because the treatment does not involve tissue evaporation or ablation, downtime is significantly reduced.

Fiber Amplifiers:

Erbium glass is widely used in fiber optics, especially in optical fiber amplifiers. Er:Glass has strong absorption and emission characteristics in the 1550 nm wavelength range, making it an ideal amplification medium for boosting the strength of optical signals, particularly in long-distance fiber optic communications.

FAQ

1. What is an Erbium Glass Laser?

An Erbium Glass Laser is a laser that uses erbium ions (Er³⁺) doped into glass as the gain medium. The laser typically emits at a wavelength of 1.54 micrometers, which originates from the transition of erbium ions from the 4I13/2 to 4I15/2 energy levels. This wavelength is known for its excellent eye safety because water has a very high absorption coefficient at 1.54 micrometers, fully absorbing the laser and preventing it from reaching the retina.

2. What are the main advantages of Erbium Glass?

The main advantages of Erbium Glass include:Eye Safety,Flexible Operating Modes,Low Power Loss.

3. What is the working principle of Erbium Glass?

The working principle of Erbium Glass depends on energy transfer between erbium ions (Er³⁺) and ytterbium ions (Yb³⁺). After absorbing pump light, the erbium ions transition to higher energy levels and emit 1.54 µm laser light through radiative transitions. Since erbium ions have low absorption efficiency, sensitizers like Yb³⁺ are often used. Yb³⁺ ions absorb near-infrared (900-1000 nm) pump light and transfer the energy to erbium ions, thus improving efficiency.

4. What are the pump sources for Erbium Glass Lasers?

The primary pump sources for Erbium Glass Lasers are:

1.Flashlamp Pumping: Uses high-energy pulses from a xenon flashlamp to excite the Erbium Glass gain medium. This traditional pumping method is suitable for high-power pulsed output.

2.Laser Diode (LD) Pumping: Laser diodes provide stable near-infrared (900-1000 nm) pump light for more efficient and stable output, especially for continuous wave (CW) mode applications.

5. What are the applications of Erbium Glass?

Erbium Glass is widely used in various fields, including:

Medical and Aesthetic Applications: Due to its excellent eye safety and non-ablative properties, Erbium Glass is extensively used for skin resurfacing, wrinkle removal, and superficial pigmentation treatments.

Distance Measurement: Besides being eye-safe, the 1.5 µm wavelength produced by Erbium Glass lasers is ideal for laser rangefinders. It has good transparency in the atmosphere, allowing the beam to travel long distances with minimal attenuation.

Fiber Optic Amplifiers: Erbium Glass is widely used in Erbium-doped Fiber Amplifiers (EDFA), especially in optical communication systems.

6. How does Erbium Glass differ from other laser crystal materials?

Compared to other laser crystal materials such as Nd:YAG or Nd:Glass, the most notable feature of Erbium Glass is its 1.54 µm wavelength, which offers superior eye safety.

7. How is thermal management optimized in Erbium Glass?

Due to Erbium Glass’s low thermal conductivity, it can accumulate heat during high-power operation, leading to thermal damage. To optimize thermal management, the following methods are commonly used:

Use of Efficient Coolants: Coolants such as deuterated water (D₂O) with good transparency can be used to reduce absorption of pump light.

Surface Reinforcement: Techniques like ion exchange can enhance the surface strength of the glass, improving its ability to handle thermal loads.

Optimized Pump Configuration: Designing smaller pump cavity gaps can reduce the absorption of surrounding water layers, thus reducing heat buildup.

8. How can the efficiency of Erbium Glass be improved?

Methods to improve the efficiency of Erbium Glass include:

Use of High Concentration Yb³⁺ Sensitizers: Increasing the concentration of Yb³⁺ ions can enhance energy transfer efficiency and optimize the performance of the Erbium Glass laser.

Optimizing Laser Diode (LD) Pumping: By selecting the appropriate LD pumping wavelength and increasing pump power, laser output efficiency can be significantly improved.

Improving Glass Matrix: Using special matrices, such as phosphate glass, combined with the characteristics of erbium and yttrium ions, can help enhance laser efficiency.

Reference

[1]Erbium (Er) glass lasers

[2]https://en.wikipedia.org/wiki/Er:glass_laser

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article