Introduction to Laser Crystals

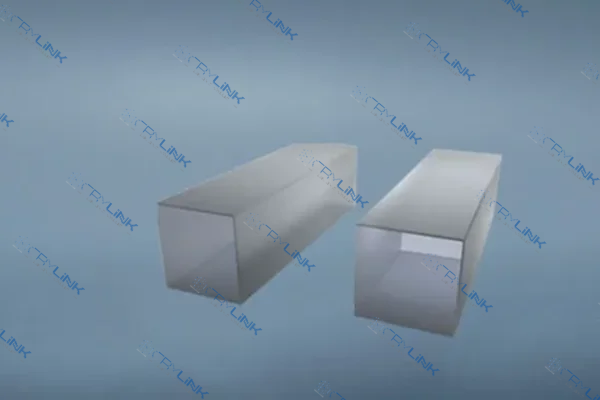

Laser crystals play a fundamental role in modern-day optics, offering impressive capabilities in power scaling and efficiency for various high-power applications. Three commonly used crystals include Yb:YAG (Ytterbium-doped Yttrium Aluminum Garnet), Yb:KGW (Ytterbium-doped Potassium Gadolinium Tungstate), and Yb:KYW (Ytterbium-doped Potassium Yttrium Tungstate). This article explores the performance, applications, and comparative aspects of these essential laser components.

Understanding the Role of Ytterbium Dopants

Understanding the critical role ytterbium (Yb) dopants play in laser crystal performance is integral to appreciating the functionality of Yb:YAG, Yb:KGW, and Yb:KYW in high-power applications. Ytterbium as a dopant operates like the conductor of an orchestra, fine-tuning each aspect of the host crystal to output an exceptional laser performance.

The ytterbium ions that replace part of the host lattice introduce energy levels within the bandgap of the host material. These energy levels are responsible for absorbing and emitting light, fundamental processes for laser operation. The absorption properties of ytterbium-doped crystals owe their effectiveness to the broad absorption bands of Yb ions. These wide bands allow for efficient absorption of pump light, facilitating the transfer of energy from the pump source to the laser medium.

The emission properties of ytterbium-doped crystals, meanwhile, benefit from the Yb ions’ wide emission spectrum. The wide emission band supports the generation of short laser pulses, which are critical for applications requiring high peak power and precision, such as micromachining and laser surgery. Moreover, the broad emission band provides the crystal with tunability, allowing the laser’s output wavelength to be adjusted according to the application’s requirements.

Thermal conductivity, another crucial attribute of laser crystals, is also enhanced by ytterbium doping. Heat generated during laser operation can lead to thermal lensing and other detrimental thermal effects, compromising the laser’s beam quality and overall performance. Ytterbium ions contribute to the excellent thermal conductivity of Yb:YAG, Yb:KGW, and Yb:KYW crystals, facilitating efficient heat dissipation and preserving the integrity and performance of the laser system.

Doping concentrations play a significant role in defining the performance of laser crystals. The high doping concentrations of ytterbium ions in Yb:YAG, Yb:KGW, and Yb:KYW crystals increase the population of active ions, allowing for more energy to be stored and released during laser operation. This increase in energy storage leads to higher output power and better laser efficiency.

In conclusion, the ytterbium dopant’s role is multidimensional, influencing and enhancing the absorption and emission properties, thermal conductivity, and doping concentrations of the host crystal. This combination of effects underscores the significance of ytterbium as a dopant and elucidates why Yb:YAG, Yb:KGW, and Yb:KYW are preferred choices in high-power laser applications. The invaluable contribution of ytterbium ions propels these crystals to the forefront of high-power laser technology, testifying to the transformative power of this remarkable element.

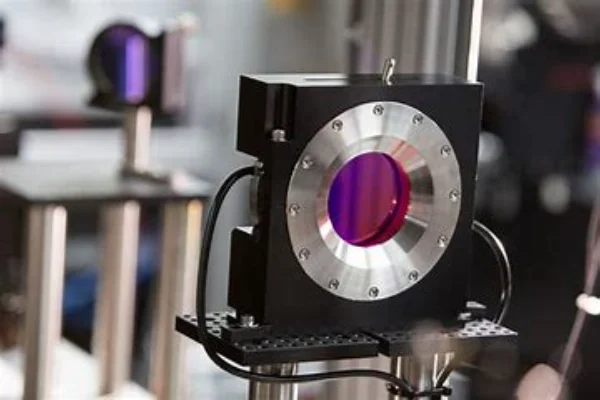

Yb:YAG, Yb:KGW, and Yb:KYW in the high-power laser systems

In the landscape of high-power laser systems, Yb:YAG (Ytterbium-doped Yttrium Aluminum Garnet), Yb:KGW (Ytterbium-doped Potassium Gadolinium Tungstate), and Yb:KYW (Ytterbium-doped Potassium Yttrium Tungstate) crystals are seen as critical components, each offering a unique blend of properties that cater to a variety of applications.

Yb:YAG is known for its exceptional thermal and mechanical properties, standing out as a crystal with a high quantum efficiency. The Yb ions in the YAG lattice have a notably broad absorption band, making them well-suited to diode-pumping. Their high thermal conductivity ensures efficient heat dissipation, making them ideal for high-power continuous-wave and pulsed lasers. These qualities find Yb:YAG employed widely in applications such as material processing, laser surgery, and scientific research. The diode-pumped solid-state lasers that utilize Yb:YAG crystals are known for their compactness, efficiency, and longevity.

Moving on to Yb:KGW, these crystals display broad absorption and emission spectra, making them well-suited for short-pulse and ultrafast laser applications. The wide absorption bandwidth allows for efficient absorption of pump light, and the broad emission spectrum supports the generation of short pulses, which is ideal for mode-locked operation. Yb:KGW’s high thermal conductivity and good mechanical properties render it an excellent candidate for high-power laser applications. Owing to these qualities, Yb:KGW is commonly found in applications such as scientific research and industrial machining, and it’s also a preferred choice for femtosecond laser systems.

Lastly, the Yb:KYW crystals offer broad tunability and high efficiency, making them the crystal of choice for diode-pumped solid-state lasers. The combination of broad emission bandwidth, excellent thermal properties, and a relatively high damage threshold make Yb:KYW versatile across a range of applications. Yb:KYW is often applied in laser marking systems, telecommunications, and scientific research due to its reliable power output and tunability.

In conclusion, while all three crystals – Yb:YAG, Yb:KGW, and Yb:KYW – are advantageous in their right, their selection often depends on the specific application requirements, with considerations around emission spectra, thermal conductivity, and overall system efficiency taking precedence.

Yb:YAG, Yb:KGW, and Yb:KYW Similarities in high doping concentration, wide emission spectrum, and excellent thermal conductivity

Despite the different materials and structures of Yb:YAG, Yb:KGW, and Yb:KYW crystals, these three laser crystals do share striking similarities, particularly regarding high doping concentrations, broad emission spectra, and excellent thermal conductivity, all of which serve to boost their performance in high-power laser systems.

High doping concentrations of ytterbium ions are a shared characteristic among Yb:YAG, Yb:KGW, and Yb:KYW crystals. This high level of doping enables the production of high power and quality laser light. Doping increases the population of active ions, allowing more energy to be stored and subsequently released in the laser operation, contributing to higher output power. This shared feature also serves to reduce the crystals’ sensitivity to thermal lensing effects and other thermally-induced distortions, further augmenting the laser system’s performance. The capacity to accommodate high ytterbium doping levels also enhances the crystals’ overall efficiency, an essential feature for high-power laser applications where energy conservation and management are of the utmost importance.

In terms of emission spectra, Yb:YAG, Yb:KGW, and Yb:KYW all demonstrate broad emission spectra, an advantageous characteristic that enhances their utility across a range of laser applications. Broad emission spectra provide these crystals with the ability to produce laser light over a wide range of frequencies. This versatility makes them suitable for various uses, from laser marking and welding to medical applications and telecommunications. Furthermore, a broad emission spectrum is particularly beneficial in ultrafast laser systems as it enables the generation of short pulses, crucial for operations requiring high peak power and precision.

Lastly, Yb:YAG, Yb:KGW, and Yb:KYW are renowned for their excellent thermal conductivity, a critical factor in high-power laser systems. Heat management is a significant concern in high-power operations, as heat accumulation can degrade the performance of the laser and even cause damage to the crystal. The high thermal conductivity of these crystals allows for effective heat dissipation, maintaining the crystal’s stability and ensuring continuous, reliable performance. This quality is vital in continuous-wave and high repetition rate pulsed laser systems, where heat generation is substantial.

In conclusion, the high doping concentrations, broad emission spectra, and excellent thermal conductivity are crucial shared characteristics that underpin the performance of Yb:YAG, Yb:KGW, and Yb:KYW in high-power laser applications. Despite their individual differences, these shared features make all three a suitable choice for a range of high-power operations, underscoring their importance in the field of laser technology.

Conclusion: Choosing the Right Laser Crystal

In conclusion, the choice between Yb:YAG, Yb:KGW, and Yb:KYW crystals is a nuanced decision that relies heavily on the specific requirements of the laser system’s application. Each crystal, while sharing certain beneficial properties such as high doping concentrations and excellent thermal conductivity, offers unique features that make it particularly suited to certain applications.

Yb:YAG, with its exceptional thermal and mechanical properties, is a reliable choice for high-power continuous-wave and pulsed lasers, used extensively in laser surgery, material processing, and scientific research. Yb:KGW, with its broad absorption and emission spectra, is well-suited for short-pulse and ultrafast laser applications, finding its use in scientific research, industrial machining, and femtosecond laser systems. On the other hand, Yb:KYW, with its broad tunability and high efficiency, is often the crystal of choice for diode-pumped solid-state lasers, laser marking systems, telecommunications, and scientific research.

In essence, the selection between Yb:YAG, Yb:KGW, and Yb:KYW must consider the laser’s intended application, the necessary emission spectra, the thermal conductivity requirements, and the overall system efficiency. By understanding the unique strengths of each crystal, you can ensure optimal performance for your specific high-power laser application. The right laser crystal is not merely about power and efficiency; it’s about finding the perfect harmony between a host of variables that ensure high performance, longevity, and reliability.

FAQs

- 1. What is the role of Ytterbium in laser crystals?

- Ytterbium, as a dopant, improves the absorption and emission properties, thermal conductivity, and doping concentrations of laser crystals.

- 2. Why is high doping concentration important in laser crystals?

- High doping concentration ensures efficient laser operation and minimizes the effect of heat accumulation.

- 3. What is broad emission spectra, and why is it significant?

- Broad emission spectra refer to the ability of laser crystals to produce a wide range of light frequencies, making them suitable for diverse applications.

- 4. What applications are Yb:YAG, Yb:KGW, and Yb:KYW suitable for?

- Yb:YAG is suitable for industrial processing, medical procedures, and defense technologies. Yb:KGW is ideal for spectroscopy, microscopy, and ultrafast applications. Yb:KYW is perfect for telecommunications, laser marking, and scientific research.

- 5. How does thermal conductivity affect the performance of laser crystals?

- High thermal conductivity allows laser crystals to dissipate heat effectively, maintaining their structure and function without significant degradation, especially in high-power applications.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Application(s) with this Article