I. Introduction: Why Your Laser System Needs a Magneto-Optic Isolator

In precision laser processing, cutting-edge scientific research, or high-speed optical fiber communication, have you ever encountered these frustrating issues?

Unexplained fluctuations in laser output power, leading to instability?

Inconsistent processing results, making repeatability difficult to guarantee?

Unexplained damage to expensive laser chips or resonant cavities?

Often, the root cause is not external, but stems from “reflected light” within the laser system itself. Whether it’s light reflected back from a workpiece surface or back-reflections generated at fiber connectors or optical lens interfaces, these “uninvited” beams re-enter the laser.

The intrusion of this back-reflected light is akin to a vehicle driving the wrong way on a highway, leading to a series of serious consequences:

It interferes with laser oscillation, causing instability in output power and frequency.

It generates noise, degrading the signal-to-noise ratio and impacting communication quality and processing precision.

In the most severe cases, concentrated retro-reflected energy can directly burn or permanently damage the delicate laser emitter, resulting in significant economic loss and project delays.

So, how can you establish a reliable “optical firewall” for your laser system?

The answer is—the Magneto-Optic Isolator.

Think of it as a “one-way valve” or “optical diode” for the laser path. It allows light to pass freely in one direction (forward) while efficiently blocking and isolating light coming from the opposite direction.

Investing in a high-quality magneto-optic isolator means:

Enhanced Stability: Ensuring consistent and reliable laser output, guaranteeing process repeatability.

Protection of Investment: Effectively safeguarding the laser source, extending its service life, and reducing maintenance costs.

Improved Performance: Reducing noise in communication systems and enhancing transmission quality.

In the following sections, we will provide an in-depth yet accessible analysis of the working principles of magneto-optic isolators, the selection of core materials, and guidance on how to choose the most suitable product based on your specific application scenario.

II. How Does a Magneto-Optic Isolator Work? – An Accessible Explanation of the Principle

To understand how this “optical one-way valve” functions, we need to grasp a key physical phenomenon—the Faraday Rotation Effect. Discovered by scientist Michael Faraday in 1845, this effect is the cornerstone of all magneto-optic isolators.

1. Core Effect: The Non-reciprocal “Optical Revolving Door”

Imagine a special revolving door: when you enter from side A, the door rotates 45 degrees clockwise, allowing you to pass through to side B. However, if you attempt to return from side B to side A, the door does not reverse its rotation but continues to rotate clockwise by another 45 degrees, effectively blocking your path.

The Faraday Rotator within the magneto-optic isolator is the core of this “revolving door.” It consists of a special magneto-optic crystal material and permanent magnets that provide a magnetic field. When linearly polarized light passes through this crystal under the influence of the magnetic field, its polarization direction rotates by a fixed angle. Crucially, the direction of this rotation depends only on the direction of the magnetic field and is independent of the propagation direction of the light. This is the non-reciprocal nature.

2. The Sophisticated Synergy of Three Key Components

A standard magneto-optic isolator operates through the coordinated work of three key components:

Polarizer: Located at the light input, it acts as an “optical grid,” transforming unpolarized natural light into linearly polarized light with a specific orientation.

Faraday Rotator: The core working region. Under the magnetic field, it precisely rotates the incident linearly polarized light by 45 degrees.

Analyzer: Located at the light output, its transmission axis is oriented at a 45-degree angle relative to the polarizer’s axis, perfectly allowing the rotated polarized light to pass through with minimal loss.

3. Differential Management of Bidirectional Light Paths

During Forward Transmission (Normal Operation):

Incident Light → Polarizer (becomes linearly polarized) → Faraday Rotator (rotated by 45°) → Analyzer (perfectly matched, highly efficient transmission)

During Reverse Transmission (Requiring Isolation):

Reflected Light → Analyzer (becomes 45° linearly polarized) → Faraday Rotator (continues rotation in the same direction by 45°, becoming 90° polarized) → Polarizer (axes are perpendicular, light is completely blocked)

The ingenuity of this process lies in the fact that regardless of the light’s direction, the Faraday Rotator “stubbornly” rotates the plane of polarization in the direction determined by the magnetic field. It is precisely this “non-reciprocity” that enables unidirectional transmission of light.

4. Key Performance Indicators

When selecting a practical device, you need to focus on two core parameters:

Isolation: Measures the ability to block backward-propagating light, typically expressed in decibels (dB). For example, 30 dB of isolation means only 0.1% of the reverse light passes through, while 40 dB means only 0.01%. Higher values indicate better protection.

Insertion Loss: Measures the optical power loss when light passes through in the forward direction. High-quality isolators can achieve insertion losses below 0.1 dB, meaning over 98% of the light power is transmitted efficiently.

Understanding this working principle allows us to see that the performance of the magneto-optic crystal directly determines the efficacy of the entire isolator. In the next chapter, we will delve into the characteristics of different magneto-optic materials to help you make a more informed selection.

III. How to Choose the Core Material? – Magneto-Optic Crystal Performance and Selection Comparison

Having understood the fundamental principles of magneto-optic isolators, you might wonder: why do the price and performance of different isolators vary so significantly? The core answer lies in the magneto-optic crystal used – the very “heart” of the isolator. The choice of crystal material directly determines whether the isolator will operate stably and efficiently within your laser system.

Core Insight: There is no “universal” magneto-optic crystal, only the optimal choice for your specific application.

In addition to the well-known garnet crystals, fluoride magneto-optic crystals have recently emerged as a research focus for next-generation magneto-optic materials due to their unique performance advantages. Below is a clear comparison of currently mainstream and emerging magneto-optic crystals and their applicable scenarios to aid your informed decision-making:

1. TGG Crystal: The “Industry Standard” with Balanced Performance

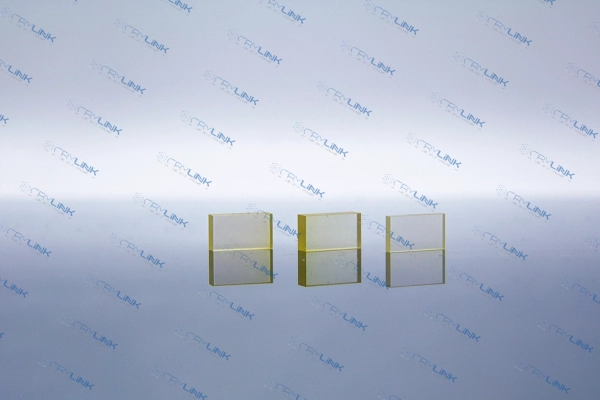

Primary Advantages: Mature technology, high reliability, and well-balanced performance. It excels in the 400-1100 nm wavelength range and is the most widely used magneto-optic material in commercial applications.

TGG Crystal

Considerations: TGG crystals cannot be used below 400 nm and exhibit an absorption peak around 490 nm. Growth processes are prone to issues like “core” structures and spiral growth, posing challenges for producing large-size, high-quality crystals.

Applicable Scenarios: Most medium-to-high-power visible to near-infrared lasers (e.g., common 1064 nm Nd:YAG lasers, fiber lasers). It remains the most mainstream and reliable choice for industrial processing, scientific research, and other fields.

2. TAG/TSAG Crystals: The “High-Performance Option” for Demanding Applications

Primary Advantages: Offer over 30% higher magneto-optic efficiency (Verdet constant) than TGG, along with superior thermal conductivity for better heat dissipation.

Considerations: TAG exhibits incongruent melting, making it susceptible to impurity phases during growth, which severely limits achievable crystal size and practical application.

Applicable Scenarios: Next-generation ultra-high-power laser systems with extremely stringent requirements for size, efficiency, and thermal management.

3. CeF3 Crystal: The “Versatile Performer” for Broadband Applications

Primary Advantages: Features the broadest transmission window, covering UV-Vis-IR wavelengths, and performs well at optical communication bands (1310 nm, 1550 nm). Its thermal lensing effect is significantly weaker than TGG’s, enabling better preservation of beam quality.

CeF3 Crystal

Unique Value: Simple composition and congruent melting properties give it significant growth advantages. It has been successfully applied in 700W high-power Faraday isolators.

Applicable Scenarios: UV lasers, high-precision applications sensitive to thermal distortion, and broadband laser systems.

4. PrF3 Crystal: The “Deep-UV Specialist”

Primary Advantages: Holds unique advantages in the deep-UV range. Its Verdet constant increases dramatically from 817 rad/(T·m) at 300 nm to 3143 rad/(T·m) at 220 nm, far exceeding TGG and CeF₃ in this region.

Considerations: Performance in the visible spectrum is inferior to TGG and CeF₃.

Applicable Scenarios: Deep-UV laser systems and specialized scientific applications.

5. KTF Crystal: The “Fiber Laser Companion” with Low Absorption

Primary Advantages: Features an extremely low absorption coefficient at communication wavelengths and low nonlinear effects. Tests indicate higher isolation and lower absorption compared to TGG under 400W laser power.

Considerations: Relatively low thermal conductivity necessitates compensation for thermal lensing to mitigate thermal effects.

Applicable Scenarios: High-power fiber lasers with stringent requirements for beam quality.

6. Other Fluoride Crystals: “Specialized Choices” for Niche Applications

EuF2-based compounds: Maintain a high Verdet constant around the 2 μm wavelength band, showing promise for developing high-power mid-infrared magneto-optic isolators.

LiTbF4: Exhibits a high magneto-optic figure of merit in the UV-Vis range and maintains performance into the deep-UV region.

NaTbF-based crystals: Possess negative optical anisotropy parameters, allowing orientation selection for minimal thermally induced depolarization. Thermal lensing effect is lower than TGG.

Summary and Selection Guidelines

When selecting a material, you can follow this approach:

First, consider the wavelength:

Deep-UV: Choose PrF3.

UV: Choose CeF3.

Visible/Near-IR (mainstream): TGG is suitable.

Mid-IR: Consider EuF2-based compounds.

Next, evaluate power requirements:

Standard high power: TGG is often sufficient.

Pursuing ultimate performance: Consider TAG/TSAG.

Concerned about thermal effects: Opt for CeF3.

Fiber lasers: Pay attention to KTF.

Finally, assess special requirements:

Broadband applications: Choose CeF3.

Large aperture needs: Evaluate ceramic options.

Mid-IR applications: Focus on novel fluorides.

Understanding the characteristics of these core materials is key to effectively communicating with suppliers and selecting the optimal “guardian” for your system. It is worth emphasizing that fluoride crystals, with advantages such as broader transmission bands and lower thermal effects, are becoming a significant direction for the development of magneto-optic materials, showing great potential particularly in overcoming the limitations of traditional garnet crystals.

IV. Confronting High-Power Challenges: How Do We Respond? – Thermal Management is Key

As laser power continues to increase, an unavoidable challenge emerges: thermal effects. This is not only the primary performance degrader for magneto-optic isolators but also a critical factor directly related to the stable operation of your laser system.

Ⅳ. Magneto-Optic Isolator Product Forms and Your Application Scenarios

Matching the Isolator to Your Specific Laser System Type

Magneto-optic isolators are not “one-size-fits-all” standard products; they require precise matching based on your specific laser system architecture. Understanding the characteristics of different product forms will provide the optimal solution for your system integration.

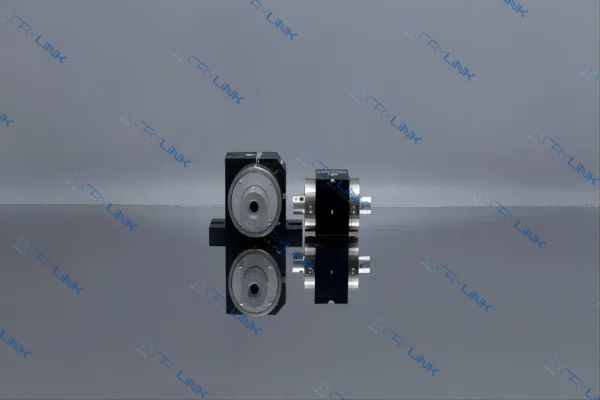

1. Free-Space Isolators

Characteristics: The beam propagates through air, with isolation function achieved via precision optical components.

Core Advantages:

High Power Handling Capacity: Clear apertures can reach 45mm or even 70mm, supporting kilowatt-level power.

Excellent Beam Quality: Preserves the laser’s original characteristics, introducing minimal wavefront distortion.

High Isolation: Typical values >33 dB, with maximum values exceeding 60 dB.

Typical Applications:

Industrial Processing: Laser welding, cutting, surface treatment.

Scientific Research: Ultrafast lasers, physics and chemistry research.

Medical Equipment: High-power medical laser systems.

Magneto-Optic Isolator

2. In-Line Isolators (Fiber-Optic)

Characteristics: Directly integrated into the fiber optic link, offering a “plug-and-play” solution.

Technical Variants:

Non-Polarization Maintaining (PM): Suitable for standard single-mode fiber systems.

Polarization Maintaining (PM): Maintains polarization state, for use with PM fiber systems.

TAP Type: Integrates a power monitoring port for real-time output power monitoring.

Core Advantages:

Compact Structure: Easy integration into existing fiber optic systems.

Excellent Stability: Insensitive to mechanical vibration and environmental disturbances.

Low Insertion Loss: Typical values <0.5 dB.

Typical Applications:

Fiber Lasers: Seed source protection, inter-amplifier isolation.

Optical Communications: DWDM systems, backbone networks.

Sensing Systems: Distributed fiber sensing, LiDAR.

3. Fiber-to-Free-Space Hybrid Isolators

Characteristics: Combine the convenience of fiber input with the flexibility of free-space optical processing.

Technical Variants:

Non-Beam-Expanding: Maintains the beam characteristics of the fiber output.

Beam-Expanding: Utilizes a beam expander to improve beam quality and reduce divergence angle.

Core Advantages:

Flexible Beam Control: Allows adjustment of beam diameter as needed.

Superior Beam Quality: Output beam features a small divergence angle.

High Stability: Combines integration convenience with performance optimization.

Typical Applications:

Fiber Laser Processing Systems: Applications requiring optimized beam quality.

Scientific Research: Experiments requiring flexible optical path configuration.

Measurement Instruments: High-precision optical measurement equipment.

4. Magneto-Optic Circulators

Characteristics: Multi-port devices enabling unidirectional transmission, used for signal separation in complex optical paths.

Technical Variants:

Non-Polarization Maintaining (PM): Suitable for intensity detection systems.

Polarization Maintaining (PM): Suitable for polarization-sensitive applications.

Core Advantages:

Signal Separation Capability: Effectively isolates input and output signals.

Compact Design: Implements complex functions within limited space.

Low Insertion Loss: Typical values <1.0 dB.

Typical Applications:

Fiber Optic Sensing: Distributed temperature, strain sensing.

Bioimaging: Optical Coherence Tomography (OCT).

Quantum Communication: Quantum Key Distribution (QKD) systems.

Selection Decision Guide

If you are a(n):

Industrial Laser System Integrator → Prioritize free-space isolators, focusing on power handling capacity and stability.

Fiber Laser Manufacturer → Opt for in-line (fiber-optic) isolators, paying close attention to insertion loss and return loss.

Research Institution User → Select flexibly based on experimental needs, valuing parameter tunability and compatibility.

Communication Equipment Provider → Choose Polarization-Maintaining (PM) in-line isolators to ensure polarization preservation.

Key Selection Parameters Checklist:

Power Capacity: Ensure a safety margin of >30%.

Wavelength Matching: Confirm performance within your specific operating wavelength range.

Interface Type: Ensure compatibility with your system’s existing interfaces (e.g., connector type).

Installation Space: Verify that the physical dimensions meet the requirements.

CHEN Wei, WANG Chengqiang, CHEN Yangguo, ZHANG Rui, DANG Yu, CHEN Jiangxu, CHEN Qiuhua, ZHANG Xing. Research Progress of Magneto-Optical Crystals and Devices[J]. Journal of Synthetic Crystals, 2025, 54(10): 1696-1713.

Chen Jie, Zhou Shengming. Review of magneto-optic materials for high power laser isolators (Invited)[J]. Infrared and Laser Engineering, 2020, 49(12): 202010.

Zhen WU, Zhonghan ZHANG, Zhen ZHANG, Shengyao ZHOU, Liangbi SU, Anhua WU. Research progress and applications of fluoride magneto⁃optical crystals[J]. Chinese Journal of Quantum Electronics, 2024, 41(2): 194.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article