Introduction

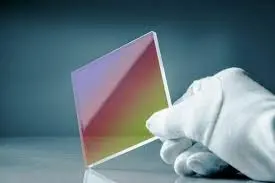

Optical films are typically composed of multiple layers of specialized materials, each with unique optical properties. These layers are meticulously engineered to manipulate light in specific ways, such as enhancing contrast or reducing glare. The composition and structure of these films play a pivotal role in determining their overall performance.

In the construction of optical films, materials like polymers, adhesives, and coatings are carefully selected and layered to achieve the desired optical effects. The thickness, refractive index, and arrangement of these layers are critical factors that dictate how light interacts with the film.

Key factors in the interaction between light and thin films

Light Transmission and Absorption

One of the primary functions of optical films is to control the transmission and absorption of light. Whether it’s a smartphone screen, camera lens, or LCD television, these films are designed to maximize the transmission of desired wavelengths while minimizing the absorption of unwanted light. Achieving this balance is essential for producing sharp and vibrant images.

High-quality optical films are engineered to transmit light efficiently, ensuring that the display or optical system delivers optimal brightness and color accuracy. Precise testing methods are employed to measure light transmission and absorption characteristics under various conditions.

Polarization and Birefringence

Many optical films are polarizing films, meaning they selectively transmit light waves that oscillate in a specific direction. These films are commonly used in applications like LCD displays and sunglasses. Understanding the polarization properties of optical films is crucial for ensuring they perform as intended.

Birefringence is another optical property that can affect the quality of optical films. It refers to the phenomenon where a material has different refractive indices for light waves polarized in different directions. Excessive birefringence can lead to image distortion and reduced clarity. Testing methods such as polarimetry are employed to assess and mitigate birefringence in optical films.

Durability and Environmental Resistance

Optical films are often exposed to harsh environmental conditions, including moisture, UV radiation, and temperature variations. Ensuring the long-term durability and resistance of these films is essential for maintaining their optical performance.

Accelerated aging tests and environmental exposure tests are conducted to assess how optical films withstand these challenges. Factors like adhesion strength, scratch resistance, and UV stability are carefully evaluated to ensure that the films can withstand real-world conditions without deteriorating.

Optical Film Testing and Evaluation

The testing and evaluation of optical films involve a range of advanced techniques and equipment. Spectrophotometers, ellipsometers, and goniometers are just a few of the tools used to measure various optical properties. These instruments enable researchers and engineers to quantify factors such as transmittance, reflectance, and colorimetry with precision.

Additionally, optical modeling software is employed to simulate and predict the behavior of optical films under different conditions. This computational approach aids in the design and optimization of optical film structures.

Testing Methods: Illuminating the Performance of Optical Films

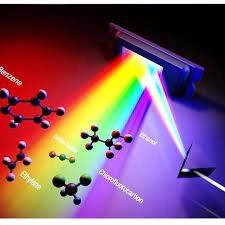

Spectral Analysis: The Gateway to Optical Clarity

Spectral analysis stands as the cornerstone of optical film testing. It delves deep into the interaction between different wavelengths of light and the film’s composition, shedding light on its optical properties. Utilizing advanced spectrophotometers, researchers and engineers can extract valuable information such as:

Transmission Rates: This metric quantifies the film’s ability to allow light to pass through it. By precisely measuring transmission rates, manufacturers can ensure that their films provide optimal brightness and clarity, making them ideal for applications like displays and lenses.

Reflection Rates: The amount of light reflected off the film’s surface is a critical factor in assessing its performance. Low reflection rates are desirable for applications where glare reduction is essential, such as in eyeglasses or camera lenses.

Absorption Rates: Understanding how much light the film absorbs is pivotal in determining its effectiveness and suitability for specific applications. Films with high absorption rates might be used in light-absorbing coatings, while those with low absorption rates are preferred for enhancing light transmission.

Laser Damage Threshold Testing: Assessing Resistance

In scientific and industrial settings, optical films often encounter high-intensity laser sources. Laser damage threshold testing is instrumental in evaluating how well the film can withstand these extreme conditions. Key objectives of this testing method include:

Identifying the Intensity Limit: Researchers aim to pinpoint the exact point at which the laser’s intensity causes damage to the film. This information is crucial for ensuring the film’s durability in environments where intense lasers are present.

Understanding Duration Effects: Beyond intensity, the duration of exposure to the laser can also influence the film’s threshold for damage. By studying how exposure time impacts the film’s integrity, engineers can design optical films that can endure extended periods of laser exposure without degradation.

Other Vital Testing Techniques

In addition to spectral analysis and laser damage threshold testing, several other testing techniques are integral to assessing optical film performance:

Scatter Measurements: Evaluating the film’s scattering properties is essential to ensure that light propagation remains consistent and free from undesirable diversions. Low scatter is essential for maintaining image clarity in optical systems.

Environmental Testing: Optical films often face a range of environmental conditions, including humidity, temperature fluctuations, and exposure to UV radiation. Subjecting the film to these conditions in controlled experiments reveals its long-term durability and stability. This type of testing is critical for determining the film’s suitability for outdoor applications or harsh environments.

Performance Evaluation: Deciphering the Test Results

Once the comprehensive testing phase has concluded, the next crucial step in the process is the thorough evaluation of the collected data. This evaluation is essential for understanding the real-world implications of the optical film’s performance. Here’s a closer look at how this evaluation process unfolds:

Benchmarking against Standards: To assess the quality and performance of the optical film, it is essential to compare the test results with established industry standards. These standards serve as reference points that help determine how the film measures up against the expectations of the industry. This benchmarking process provides a clear indication of whether the film meets, exceeds, or falls short of the quality standards, guiding manufacturers in making necessary improvements.

Functional Analysis: The film’s performance data, including its transmission, reflection, and absorption rates, are scrutinized to determine its suitability for specific applications. For example, if a film exhibits exceptional light transmission and minimal reflection, it may be deemed suitable for applications requiring high clarity, such as display screens or camera lenses. Conversely, films with high absorption rates may find their niche in light-absorbing coatings or specialized optical devices. This functional analysis is critical for optimizing the film’s utility in various industries.

Durability Insights: The insights gained from laser damage threshold testing and environmental exposure tests are instrumental in assessing the film’s durability and long-term performance. These tests reveal how well the film can withstand harsh conditions, high-intensity light sources, and environmental stressors. Conclusions drawn from these insights help manufacturers make informed decisions regarding the film’s maintenance requirements, expected lifespan, and resistance to wear and tear.

Concluding Thoughts: The Quintessence of Testing & Evaluation

In the realm of optical films, ensuring optimal performance is far from a luxury; it’s an absolute necessity. Rigorous testing and meticulous evaluation go beyond simply assessing a film’s quality—they are integral to ensuring the success of the systems into which these films are integrated. Whether it’s a groundbreaking scientific research project, a high-end display technology, or a commonplace consumer gadget, the clarity, efficiency, and durability of optical films play a pivotal role in enhancing the user experience and achieving desired outcomes.

Therefore, investing time, resources, and expertise into the testing and evaluation of optical films is not just about the films themselves—it’s about the bigger picture they seamlessly fit into. The continued pursuit of excellence in optical film testing and evaluation ultimately leads to advancements in technology, improved product quality, and enhanced user satisfaction, making it an indispensable aspect of modern innovation and industry standards.

FAQs

- 1.How often should optical films undergo performance testing?

Routine testing is recommended, especially if the film is part of a system undergoing regular updates or modifications. - 2.Are there industry-specific standards for optical film testing?

Yes, different industries may have their own set standards. For example, aerospace and defense might have different criteria compared to consumer electronics. - 3.Can optical films improve with subsequent iterations post-testing?

Absolutely. Testing often reveals areas of improvement, leading to enhanced versions of the films. - 4.Is environmental testing mandatory for all optical films?

While not always mandatory, it’s highly recommended, especially for films used in fluctuating or extreme conditions. - 5.What’s the most critical factor in optical film performance?

While all factors like transmission, reflection, and absorption are vital, the most critical factor often depends on the film’s intended application.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article