Tm:YAG

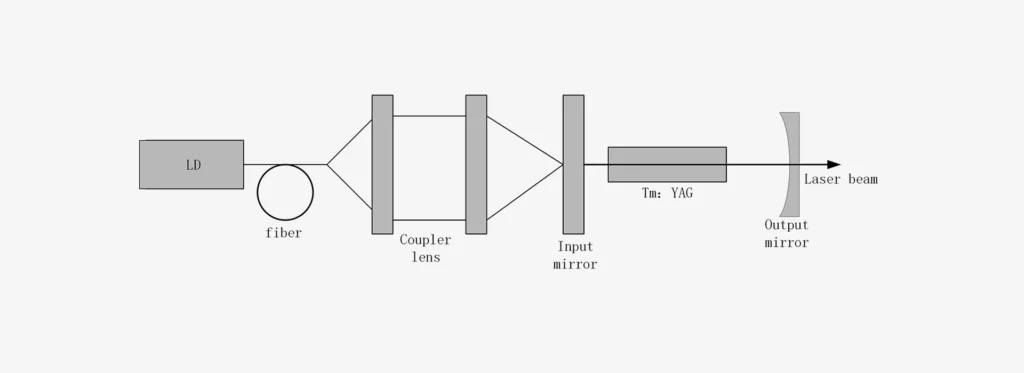

Tm: YAG operating on the 3H4 –3H6 transition in the 0.82 μm wavelength range. It can be pumped with efficient diode lasers in the 0.78 – 0.8 μm wavelength range. The transition has a small quantum defect for low thermal dissipation. The upper state lifetimes can be long, on the order of a millisecond for good energy storage. It also has sufficient gain bandwidth to support sub-ps-long pulses, depending on the host material and operation temperature.

Compared with the single-crystal material, the transparent ceramic materials combine the advantages of single crystals and glasses. The transparent ceramic materials are fabricated by solid-state reaction and vacuum sintering. So, they possess good optical and thermal properties as fine as single crystals and can be fabricated with large size and high concentration. Furthermore, they also have other superiorities, such as a short fabrication period, less cost, and multifunctional samples.

Features of Tm: YAG:

- High quantum efficiency

- High efficiency with LD pump

- Long upper state lifetime

- Sufficient gain bandwidth

- Small quantum defect

- High damage threshold

Material Specifications

| Tm Concentration Tolerance(atm%) | Tm:0.5~5at% |

| Orientation | [111],<5º |

| Parallelism | ≤10″ |

| Vertical | ≤5′ |

| Surface Quality | 10-5 (MIL-O-13830A) |

| Wavefront Distortion | ≤ 0.125λ/25 mm @632.8nm |

| Surface Flatness | λ/8@632nm |

| Clear Aperture | >95% |

| Chamfering | 0.15±0.05mm |

| Size | D: 2~10mm,L: 3~150mm |

| Coating | AR: ≤0.25% @2μm |

Physical and Chemical Properties

| Crystal Structure | Cubic Crystal System |

| Lattice Constant | 12.01 Å |

| Density | 4.56±0.04g/cm3 |

| Melting Point | 1970℃ |

| Thermal Conductivity/ W / m / K @ 20℃ | 14W/m/K@20℃; 10.5W/m/K@100℃ |

| Specific Heat(J/g.cm3@0-20℃) | 0.59 |

| Thermal-optical Coefficient(dn / dT) | 7.3×10-6/K |

| Thermal Expansion | [100]: 8.2×10-6/K@0~250℃ |

| [110]: 7.7×10-6/K@0~250℃ | |

| [111]: 7.8×10-6/K@0~250℃ | |

| Mohs Hardness | 8.5 |

| Young's Modulus | 3.17×104Kg/mm2 |

| Shear Modulus | 310GPa |

| Extinction Ratio | ≥ 25dB @632.8nm |

| Tensile Strength/ Gpa | 0.13~0.26 |

| Solubility | Insoluble in water, slightly soluble in common acid |

| Poisson Ratio | 0.25 |

| Thermal Shock Resistance | 790W/m |

Optical and Spectral Properties

| Laser Transition | 3F4→3H6 |

| Laser Wavelength | 1.87~2.16μm |

| Temperature Dependence of Refractive Index | 7.3 10-6/K |

| Absorption Cross Section | 7.5×10-21cm2 |

| Diode Pump Band | 785nm, 680nm |

| Emission Cross Section@ 2013nm | 2.9×10-20 cm2 |

| Fluorescence Lifetime | 11ms |

| Refractive Index@ 632nm | 1.83 |

References

| [1] Liu X , Huang H , Zhu H , et al. A modified model for the LD pumped 2 μm Tm:YAG laser: Thermal behavior and laser performance[J]. Optics Communications, 2014, 332:332-338. |

| [2] C C T W A , B F C , C Y L J . A simple method to estimate the thermal focal length of LD-end-pumped Tm:YAG crystal at room temperature – ScienceDirect[J]. Optik, 2015, 126( 13):1300-1302. |

| [3] Wang C , Niu Y , Liu W , et al. A theoretical and experimental investigation for wavelength switchable TmYAG laser modulated by Tm:YAG crystal length[J]. Optics & Laser Technology, 2015, 68:18-22. |

| [4] Bernard J E , Whitford B G , Madej A A . A Tm:YAG laser for optical frequency measurements: mixing 148 THz light with CO2 laser radiation[J]. Optics Communications, 1997, 140(1-3):45-48. |

| [5] Quehl G , J Grünert, Elman V , et al. A tunable dual frequency Tm:YAG laser[J]. Optics Communications, 2002, 190(1-6):303-307. |

| [6] A, Rameix, and, et al. An efficient, diode-pumped, 2 μm Tm:YAG waveguide laser[J]. Optics Communications, 1997. |

| [7] Ju Y , Wu C , Qiang W , et al. Diode-end-pumped linear-polarized single-frequency Tm:YAG laser at room temperature[J]. Optics Communications, 2012, 283(1):93-97. |

| [8] Sidorowicz, Agata, Nakielska, et al. Effect of Tm2O3 doping on microstructure and optical properties of Tm:YAG ceramics.[J]. Ceramics International, 2015. |

| [9] C Bollig and W.A Clarkson and R.A Hayward and D.C Hanna. Efficient high-power Tm:YAG laser at 2 μm, end-pumped by a diode bar[J]. Optics Communications, 1998. |

| [10] Zhang S , Wang X , Kong W , et al. Efficient Q-switched Tm:YAG ceramic slab laser pumped by a 792 nm fiber laser[J]. Optics Communications, 2013, 286(Complete):288-290. |

| [11] Cheng L , Shen D , Jie S , et al. Flash-lamp pumped normal-mode and Q-switched Cr–Tm:YAG laser performance at room temperature[J]. Optics Communications, 1999, 164(1-3):63-67. |

| [12] Xu X , Feng W , Xu W , et al. Growth and spectral properties of Yb,Tm:YAG crystal[J]. Journal of Alloys and Compounds, 2008, 462(1-2):347-350. |

| [13] Jin L , Liu P , Liu X , et al. High average power of Q-switched Tm:YAG slab laser[J]. Optics Communications, 2016, 372:241-244. |

| [14] Zou Y , Wei Z , Wang Q , et al. High-efficiency diode-pumped Tm:YAG ceramic laser[J]. Optical Materials, 2013, 35(4):804-806. |

| [15] Wu C , Fei C , Ju Y , et al. High-power single-longitudinal-mode operation of Tm:YAG laser using Fabry–Perot etalons and volume Bragg grating[J]. Optics Communications, 2012, 285(10-11):2693-2696. |

| [16] Xu W , Xu X , Wu F , et al. Infrared to Visible Upconversion Fluorescence in Yb,Tm :YAG Single Crystal[J]. Optics Communications, 2007, 272(1):182-185. |

| [17] Wu C , Ju Y , Qiang W , et al. Injection-seeded Tm:YAG laser at room temperature[J]. Optics Communications, 2011, 284(4):994-998. |

| [18] Ma Q L . Light scattering and 2-μm laser performance of Tm:YAG ceramic[J]. Optics Communications, 2011, 284(6):1645-1647. |

| [19] T Chanelière, Bonarota M , Damon V , et al. Light storage protocols in Tm:YAG[J]. Journal of Luminescence, 2009, 130(9):1572-1578. |

| [20] Jianguo, Li, Tao, et al. Measurement of output characteristics of Tm:YAG laser at 25–300K[J]. Optics Communications, 2015, 334:118-121. |

| [21] Merkel K D , Mohan R K , Cole Z , et al. Multi-Gigahertz radar range processing of baseband and RF carrier modulated signals in Tm:YAG[J]. Journal of Luminescence, 2004, 107(1/4):62-74. |

| [22] Louchet A , Du Y L , Brouri T , et al. Optical investigation of nuclear spin coherence in Tm:YAG[J]. Solid State Sciences, 2008, 10(10):1374-1378. |

| [23] Output characteristics of acousto-optical cavity dumped Tm:YAG ceramic laser[J]. Optik – International Journal for Light and Electron Optics, 2016, 127(6):3175-3178. |

| [24] Sidorowicza A , Wajlera A , Helena Węglarza, et al. Precipitation of Tm2O3 nanopowders for application in reactive sintering of Tm:YAG[J]. Ceramics International, 2014, 40(7):10269-10274. |

| [25] Zhang W X , Pan Y B , Zhou J , et al. Preparation and characterization of transparent Tm:YAG ceramics[J]. Ceramics International, 2011, 37(3):1133-1137. |

| [26] R Müller, Fuhrberg P , Teichmann H O , et al. Pulsed and cw Cr,Tm:YAG laser with simultaneous diode and flashlamp excitation[J]. Optics & Laser Technology, 2005, 37(7):570-576. |

| [27] Chunting Wu⁎, Jiang Y , Wang C , et al. Pulse-diode-intermittent-pumped 2-µm acousto-optically Q-switched Tm:YAG laser[J]. Infrared Physics & Technology, 2019, 96:151-154. |

| [28] Ferrier A , Ilas S , Goldner P , et al. Scandium doped Tm:YAG ceramics and single crystals: Coherent and high resolution spectroscopy[J]. Journal of Luminescence, 2017:S0022231317316599. |

| [29] Fei B J , Huang J Q , Guo W , et al. Spectroscopic properties and laser performance of Tm:YAG ceramics[J]. Journal of Luminescence, 2013, 142(Complete):189-195. |

| [30] Wu, C, T, et al. Thermal effect and laser characteristics of LD end-pumped CW Tm:YAG laser at room temperature[J]. Journal for Light and Electronoptic, 2017. |

If you are intereted in Tm:YAG, please click the button below to enquire or ask for a samplel.

Related article(s) with Tm:YAG:

Related case study with Tm:YAG:

There is no related case study with this product, please visit case study page to find out more.

Related solution(s) with Tm:YAG:

Related video(s) with Tm:YAG:

There is no related video(s), please visit videos page to find out more.