Chapter 1: Introduction to Nd YAG Crystals

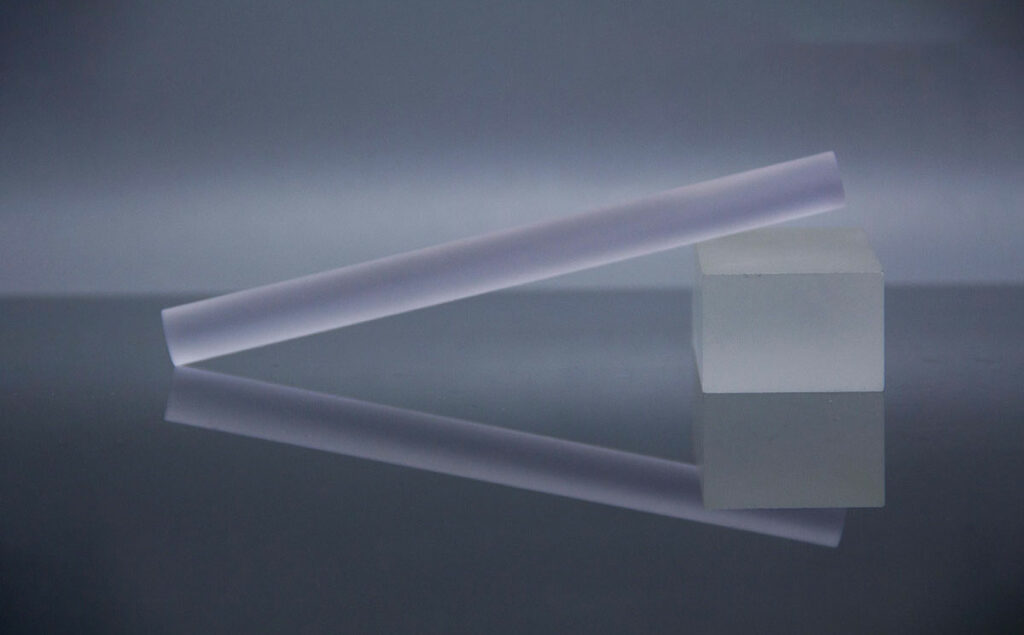

Nd YAG crystals are a type of laser crystal that has become an essential component of various laser systems. These crystals comprise a combination of neodymium, yttrium, aluminium, and garnet, hence the acronym Nd YAG. Combining these elements produces an optically transparent crystal with high thermal conductivity and is resistant to damage from laser radiation.

Nd YAG crystals have several unique properties that make them ideal for use in laser technology. One of the most important properties of Nd YAG crystals is their high gain coefficient.

The gain coefficient refers to the measure of how much the crystal amplifies light passing through it. Nd YAG crystals have a high gain coefficient, which means that they can amplify light efficiently, producing high-power laser beams.

Another critical property of Nd YAG crystals is their high damage threshold. The damage threshold is the amount of laser energy a material can absorb before it starts to break down. Nd YAG crystals have a high damage threshold, making them resistant to damage from high-powered lasers. This makes them ideal for high-power laser systems such as those used in industrial and military applications.

Nd YAG crystals also have low optical losses, so they can transmit laser light efficiently without losing energy. This makes them ideal for use in laser resonators, where it is important to minimize the loss of laser energy to produce a high-power laser beam.

In addition to their unique properties, Nd YAG crystals have several advantages over other laser materials. One of the most significant advantages of Nd YAG crystals is their long operating lifetime. Nd YAG crystals have a long lifetime, meaning they can operate for thousands of hours before needing to be replaced.

Nd YAG crystals are also highly efficient so that they can convert a high percentage of input power into laser light output. This high efficiency makes Nd YAG lasers more cost-effective than other laser systems, requiring less power to produce the same laser output.

Finally, Nd YAG crystals are highly versatile, as they can produce laser beams at various wavelengths. Nd YAG lasers can produce laser beams at a fundamental wavelength of 1064 nm and at second and third harmonic wavelengths of 532 nm and 355 nm, respectively. This versatility makes Nd YAG lasers suitable for a range of applications.

Overall, Nd YAG crystals are a critical component of various laser systems. Their unique properties and advantages make them ideal for use in high-power laser applications such as cutting, welding, and drilling of metals, as well as in scientific research and medical applications. In the following chapters, we will explore the manufacturing and processing of Nd YAG crystals, their laser properties, and their various applications in greater detail.

Chapter 2: Manufacturing and Processing of Nd YAG Crystals

Nd YAG crystals are typically grown using the Czochralski method, which involves melting the constituent elements in a high-temperature furnace and slowly cooling them to produce a single-crystal ingot. This method produces a high-quality crystal with low defects and high optical homogeneity, making it ideal for laser applications.

The first step in the manufacturing of Nd YAG crystals is the preparation of high-purity starting materials. This typically involves the purification of yttrium, aluminium, and neodymium using chemical processes to remove impurities such as iron and chromium, which can affect the crystal’s optical properties.

Once the starting materials are prepared, they are mixed in the correct stoichiometric ratio and melted in a high-temperature furnace. The melt is then slowly cooled at a controlled rate to produce a single-crystal ingot. The cooling rate is critical in determining the quality of the crystal, as too rapid cooling can result in cracking and defects in the crystal.

Once the ingot is formed, it is sliced into wafers using a diamond saw. The wafers are then polished to remove any surface defects and to achieve the desired optical quality.

Nd YAG crystals can also be doped with other elements to produce crystals with specific laser properties. For example, chromium-doped Nd YAG crystals can produce laser beams at a wavelength of 1.34 microns, ideal for medical applications such as tattoo removal and hair removal.

Another process used to enhance the properties of Nd YAG crystals is annealing. Annealing involves heating the crystal to a high temperature and then slowly cooling it to remove defects and improve its optical homogeneity. Annealing can also enhance the crystal’s resistance to optical damage and increase its lifetime.

Overall, the manufacturing and processing Nd YAG crystals require careful control of the starting materials, the melting and cooling process, and the post-processing steps, such as slicing and polishing. These steps are critical in producing high-quality Nd YAG crystals with the desired laser properties for various applications. In the following chapters, we will explore the various laser properties of Nd YAG crystals and their applications in greater detail.

Chapter 3: Optical Properties of Nd YAG Crystals

Nd YAG crystals possess several unique optical properties ideal for laser applications. This chapter will explore some of these properties in greater detail.

- Refractive Index: Nd YAG crystals have a high refractive index, meaning they bend light more than most other materials. This property allows them to focus laser beams to a very small spot, making them ideal for precision laser applications such as micro-machining and micro-drilling.

- Nonlinear Optical Properties: Nd YAG crystals exhibit nonlinear optical properties, which means they can generate new frequencies of light when exposed to high-intensity laser beams. This property is exploited in applications such as frequency doubling and optical parametric amplification.

- High Damage Threshold: Nd YAG crystals have a high damage threshold, meaning they can withstand exposure to high-intensity laser beams without sustaining damage. This property makes them ideal for high-power laser applications such as laser cutting and welding.

- Polarization Properties: Nd YAG crystals are birefringent, splitting incident light into two polarizations. This property is exploited in applications such as electro-optic modulation and Pockels cells.

- Thermal Conductivity: Nd YAG crystals have high thermal conductivity, meaning they can dissipate heat effectively. This property is essential in high-power laser applications, as it helps to prevent thermal damage to the crystal.

In addition to these properties, Nd YAG crystals can be doped with other elements to produce specific laser properties. For example, neodymium doping can produce laser beams at a wavelength of 1.064 microns, which is ideal for industrial and medical applications such as laser cutting, welding, and tattoo removal. Chromium doping, as mentioned in the previous chapter, can produce laser beams at a wavelength of 1.34 microns, ideal for medical applications such as hair removal.

Chapter 4: Applications of Nd YAG Crystals in Laser Technology

Nd YAG crystals have a wide range of applications in laser technology due to their unique optical properties. This chapter will explore some of the most common applications of Nd YAG crystals.

- Industrial Applications: Nd YAG lasers are commonly used in industrial applications such as laser cutting and welding due to their high power and precise beam control. Nd YAG lasers can cut and weld various materials, including metals, ceramics, and plastics.

- Medical Applications: Nd YAG lasers are also widely used in medical applications such as skin rejuvenation, hair removal, and tattoo removal. The laser’s high power and precise beam control make it ideal for these applications, as it can target specific areas without damaging surrounding tissue.

- Military Applications: Nd YAG lasers have been used in military applications such as range-finding and target designation due to their high power and precise beam control.

- Communications Applications: Nd YAG lasers are also used in communications applications such as fibre optic amplifiers and repeaters. The laser’s high power and precise beam control are ideal for boosting weak signals in fibre optic networks.

- Aerospace Applications: Nd YAG lasers are also used in aerospace applications such as lidar and remote sensing. The laser’s high power and precise beam control allow it to accurately measure distances and map terrain from a distance.

- Artistic Applications: Nd YAG lasers have also found use in artistic applications such as laser engraving and etching. The laser’s precise beam control allows artists to create intricate designs on various materials.

- Nd YAG lasers are also widely utilized in research and development, notably in physics, chemistry, and materials science. Researchers may examine the characteristics of materials at the microscopic level thanks to the laser’s precision beam control, which enables the creation of novel materials and technologies.

Nd YAG crystals are widely used in laser technology for various purposes, including industrial, medicinal, research, and aesthetic purposes. The laser’s high power and precision beam control make it a flexible tool for various applications.

Chapter 5: Advantages of Nd YAG Crystals in Laser Technology

Nd YAG crystals offer many advantages over other types of laser crystals, making them a popular choice for a wide range of applications. This chapter will explore some key advantages of Nd YAG crystals in laser technology.

- High Power: Nd YAG lasers can produce extremely high power outputs, making them ideal for industrial and medical applications that require precise beam control and high energy density.

- Versatility: Nd YAG crystals can be used with many pump sources, including flash lamps and diode lasers. This versatility allows for various applications and makes Nd YAG lasers popular in many industries.

- Long Operating Life: Nd YAG crystals have a long operating life, making them a cost-effective choice for many applications. The crystals are highly resistant to thermal and optical damage, allowing them to maintain their performance over time.

- High Efficiency: Nd YAG lasers have a high conversion efficiency, which converts a high percentage of the pump energy into laser light. This high efficiency makes Nd YAG lasers a cost-effective choice for many applications.

- Narrow Pulse Width: Nd YAG lasers can produce very short pulse widths, making them ideal for high-precision and control applications. The laser’s narrow pulse width allows for precise material removal and cutting, making it a popular choice for industrial applications.

- High Beam Quality: Nd YAG lasers have a high beam quality, meaning the laser beam is highly uniform and focused. This high beam quality allows for precise material processing and cutting, making Nd YAG lasers popular in many industries.

- Stability: Nd YAG crystals are highly stable, allowing consistent performance over time. This stability is especially important in scientific and research applications, where precise and consistent results are essential.

- Compact Size: Nd YAG lasers can be designed to be very compact, making them ideal for applications where space is limited. Nd YAG lasers’ compact size makes them easier to integrate into existing systems, making them a popular choice for many industries.

Overall, Nd YAG crystals offer many advantages over other types of laser crystals, including high power, versatility, long operating life, high efficiency, narrow pulse width, high beam quality, stability, and compact size. These advantages make Nd YAG lasers a popular choice for a wide range of applications in many different industries.

Nd YAG crystals have various applications in various industries due to their excellent properties and versatility. Nd YAG lasers are used in industrial manufacturing, medical procedures, scientific research, defence and aerospace, communication and information technology, environmental and geological studies, art conservation, and entertainment. The high power, beam quality, and precision of Nd YAG lasers make them an attractive option for many applications.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article