Introduction

In the evolving world of optoelectronics and laser technology, materials play a critical role in defining performance, versatility, and applicability. Among these, YCOB crystals and their doped counterpart, Nd:YCOB crystals, stand out due to their distinctive properties and versatile applications. In this comprehensive guide, we dive deep into these materials, highlighting their unique attributes, comparing their performance metrics, and showcasing their varied roles in modern technological applications.

Understanding YCOB Crystals

YCOB Crystals, characterized as Yttrium Calcium Oxyborate, play an instrumental role in the realm of optics, primarily due to their non-linear optical attributes. Stemming from their unique molecular structure, these crystals have set new paradigms in optoelectronic applications, most notably in frequency doubling of high-power lasers and other electro-optical systems. But what’s the science behind their widespread acclaim?

To begin with, the unmatched transparency range of YCOB crystals is truly remarkable. Spanning from the ultraviolet to the far-infrared spectrum, this wide range allows them to be versatile in a plethora of applications. Be it in cutting-edge research laboratories or in commercial electronic devices, their adaptability ensures they remain an asset wherever precise optical manipulation is needed.

Furthermore, when discussing high-power lasers, the intensity and energy they carry can be detrimental to many materials. However, YCOB crystals exhibit a commendable damage threshold, enabling them to withstand such high-power beams without succumbing to degradation. This resilience makes them indispensable in operations where reliability and durability are paramount. In simple terms, they offer a dependable performance even in the most rigorous conditions.

Yet another notable property of YCOB crystals is their thermal stability. In many optical applications, even minor temperature fluctuations can disrupt performance. But with YCOB, the deviations are minimal, allowing optical systems to function efficiently irrespective of external temperature variations.

However, like all materials, YCOB crystals aren’t devoid of challenges. Their fabrication process, for instance, is intricate, necessitating a fine balance of expertise, precision, and specialized equipment. This, in turn, translates to elevated production costs, making them a pricier option compared to some alternatives. Another concern is their susceptibility to moisture. Long-term exposure to humid conditions can potentially compromise their optical efficiency, necessitating protective measures to prolong their lifespan.

In summation, while YCOB crystals present an array of advantages that position them at the forefront of optoelectronic advancements, it’s imperative to be cognizant of their inherent limitations. Balancing their benefits against their challenges is key to harnessing their full potential.

Delving into Nd:YCOB Crystals

Nd:YCOB Crystals, a term which might sound esoteric to the uninitiated, refer to YCOB crystals that have undergone a special treatment, namely the doping with Neodymium (Nd). This process, though complex, brings forth a medley of enhanced attributes that are invaluable, especially in the optoelectronic world.

At the heart of the value proposition of Nd:YCOB Crystals lies their amplified performance in laser devices. By introducing Neodymium, the resultant laser beams not only exhibit increased clarity but also demonstrate remarkable consistency. For professionals relying on precise optical outputs, this level of precision and clarity can be game-changing. Picture a solid-state laser application where every beam’s uniformity can spell the difference between success and failure; it’s in such scenarios that Nd:YCOB truly shines.

Furthermore, durability in the realm of crystals, especially those used in high-intensity applications, cannot be overstated. Nd, being a robust element, fortifies the structure of the YCOB crystal. This enhanced durability ensures that the crystal stands the test of time, even in demanding environments, offering prolonged service without frequent need for replacements or maintenance.

But perhaps one of the most enticing aspects of Nd:YCOB Crystals is their versatility. By modifying the inherent properties of YCOB through doping, the range of applications where these crystals can be employed multiplies. Advanced technological setups, which often necessitate bespoke materials with very specific properties, can benefit immensely from the nuanced capabilities of Nd:YCOB.

However, perfection is elusive. The process of doping YCOB with Nd isn’t straightforward. Striking the optimal balance during doping can be a meticulous endeavor, demanding expertise and precision. A slight oversight can result in a product that falls short of desired attributes. This intricacy, coupled with the requirement of additional resources and processes, invariably affects the cost structure, making Nd:YCOB pricier than its undoped kin.

In the grand tapestry of optoelectronics, Nd:YCOB Crystals are a testament to how material science can push the boundaries of what’s possible, but it’s also a reminder that every advancement comes with its own set of challenges.

Performance Comparison: YCOB vs. Nd:YCOB

When navigating the intricate world of optoelectronics, the choice of materials can often be the pivotal factor in determining the success of a project. In the spotlight here are two formidable contenders: YCOB and its doped counterpart, Nd:YCOB. While both have carved their niche in the optical realm, a closer examination reveals distinct differences that cater to specific application needs.

One of the most apparent distinctions lies in laser efficiency. The Nd:YCOB variant stands as a testament to the prowess of material science. By doping YCOB with Neodymium, a significant enhancement in laser performance is achieved. This augmentation translates to sharper, clearer, and more consistent laser outputs, making Nd:YCOB an ideal choice for applications where precision and clarity are paramount. This is not to downplay the efficiency of YCOB; it’s just that its Neodymium-doped counterpart takes the game a notch higher in this department.

Shifting the lens to thermal attributes, while both crystals are laudable in their thermal properties, the undoped YCOB crystal has a slight advantage. Its intrinsic composition renders it more resistant to temperature-induced anomalies. In environments where temperature fluctuations are common, this can be a crucial determinant. Systems built with YCOB can, therefore, function seamlessly and with minimal deviations even when external conditions aren’t optimal.

But with great power, often comes increased cost. The introduction of Neodymium in the crystal matrix, while imparting several beneficial attributes, also brings with it an added layer of complexity in the manufacturing process. This complexity, coupled with the resources and expertise needed for the precise doping process, tends to drive up the costs. As a result, Nd:YCOB typically carries a higher price tag compared to its undoped counterpart. On the other hand, YCOB, being free from such additional processes, presents a more economical option without compromising significantly on performance.

In conclusion, the choice between YCOB and Nd:YCOB isn’t a matter of which is superior in an absolute sense, but rather which is better suited for a particular application’s demands. Whether it’s the enhanced laser efficiency of Nd:YCOB or the cost-effectiveness and thermal resistance of YCOB, understanding these nuanced differences is key to making informed decisions in the field of optoelectronics.

Applications Galore

Diving deep into the realm of optoelectronics, one quickly realizes that the potential applications for materials like YCOB and Nd:YCOB are vast and continually evolving. These crystals, with their exceptional properties, are not just confined to labs but have made their way into real-world applications, driving innovation and shaping the future of technology.

YCOB, with its impressive wide transparency range, has become the darling of laser technology. Particularly in frequency doubling of lasers, YCOB stands out. This process essentially involves converting a photon of one frequency into two photons of double the frequency, and the result is a laser beam with a halved wavelength. Given the unique transparency attributes of YCOB, it is incredibly efficient in this doubling process, ensuring that lasers produce beams of the desired frequency with minimal energy loss.

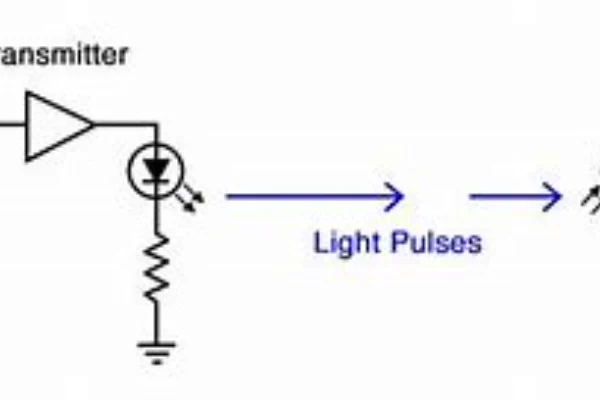

Furthermore, the world of signal modulation has also greatly benefited from YCOB. Electro-optical modulation, a process that involves the use of light to modulate electrical signals, requires materials that can interact with both light and electrical signals seamlessly. YCOB’s unique properties, particularly its wide transparency range and non-linear optical characteristics, make it an optimal choice for such applications. With YCOB in the mix, the conversion between electrical signals and light becomes more efficient, ensuring clearer communication and signal transmission.

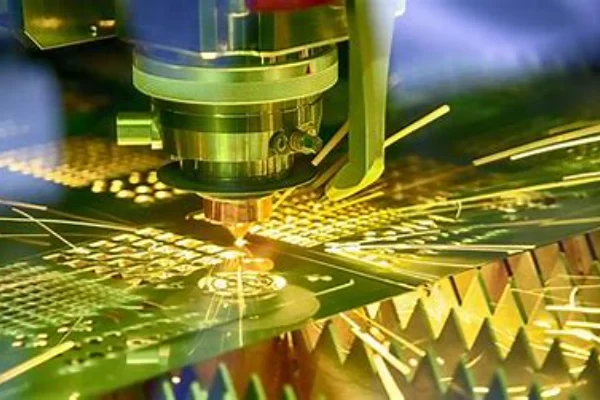

On the other hand, when it comes to Nd:YCOB, its prowess in laser technology is unparalleled, especially in the domain of solid-state lasers. These lasers, known for their stability and reliability, require materials that can amplify light without significant losses. Thanks to the Neodymium doping, Nd:YCOB crystals excel in this regard, producing powerful and consistent laser beams, which are crucial in applications ranging from medical procedures to industrial machining.

Moreover, the world of advanced optoelectronics is abuzz with the potential of Nd:YCOB. As technology continues to miniaturize and demands more from its components, Nd:YCOB, with its versatile properties, is emerging as a frontrunner. From sensors that can detect minute changes in environmental conditions to communication devices that require rapid signal transmission, the capabilities of Nd:YCOB are being harnessed in groundbreaking ways.

In essence, both YCOB and Nd:YCOB crystals, while sharing certain core attributes, have carved out unique spaces for themselves in the tech world. As research continues and technology evolves, it’s evident that the applications of these materials will only expand, further solidifying their role in shaping the future of optoelectronics.

Conclusion

The debate between YCOB and Nd:YCOB crystals isn’t about which is superior, but rather, which is more suitable for a specific application. Both these materials have carved a niche for themselves in the world of optoelectronics and laser technology. Their unique attributes, coupled with their respective advantages and limitations, make them invaluable assets in various technological setups. As technology continues to evolve, the relevance and applicability of these crystals are bound to grow, further solidifying their place in modern applications.

FAQs

- What is the primary difference between YCOB and Nd:YCOB crystals?

- Nd:YCOB crystals are YCOB crystals doped with Neodymium (Nd), enhancing certain properties, particularly in laser performance.

- Why are YCOB crystals favored for frequency doubling?

- YCOB crystals possess a wide transparency range, making them apt for frequency doubling of lasers.

- How does Neodymium doping affect the cost of the crystal?

- Doping with Neodymium can elevate the overall cost of the crystal due to additional processes involved.

- Is there a significant difference in the thermal resistance of both crystals?

- Both showcase impressive thermal properties, but YCOB tends to have a slight advantage in thermal resistance.

- Which crystal is more suitable for solid-state lasers?

- Nd:YCOB crystals, with their enhanced laser attributes, are preferred for solid-state lasers.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article