The quality of BBO crystals plays a crucial role in determining the efficiency and reliability of optoelectronic devices that use frequency doubling. High-quality BaB2O4 crystals are essential for achieving high conversion efficiency, low loss, and a narrow spectral bandwidth. In this chapter, we will discuss the fabrication techniques for high-quality BBO crystals, including crystal growth, polishing, and coating.

Crystal Growth Techniques

The quality of BBO crystals depends on the crystal growth technique used to fabricate them. There are several crystal growth techniques available for BBO crystals, including the Czochralski method, the Bridgman method, and the top-seeded solution growth (TSSG) method. The Czochralski method is the most commonly used method for fabricating BaB2O4 crystals due to its high crystal quality and low cost. The Bridgman method is used for high-quality crystals, while the TSSG method is used for producing large single crystals.

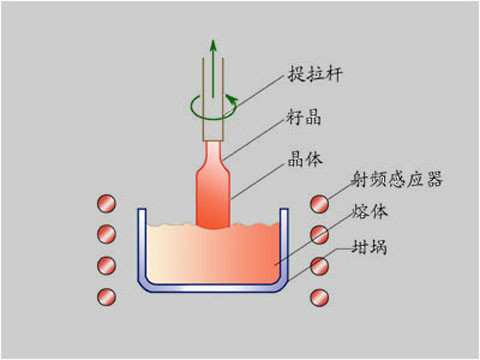

Czochralski Method

The Czochralski method is a widely used crystal growth technique for various crystals, including BBO nonlinear crystals. It involves the use of a high-temperature furnace, which melts the raw materials, and a seed crystal, which is slowly pulled from the melt. As the seed crystal is pulled, it acts as a template for the crystal growth, allowing for the production of high-quality, single-crystal BBO nonlinear crystals.

The Czochralski method is advantageous because it enables the production of high-quality BBO nonlinear crystals with low defect density and high purity. The use of a seed crystal allows for controlled crystal growth, and the high-temperature conditions promote the formation of a large, high-quality crystal. However, the Czochralski method can be time-consuming, and the high-temperature conditions can lead to thermal stress, which affects the crystal quality.

Flux Growth

Flux growth is another crystal growth technique used for producing high-quality BBO nonlinear crystals. It involves the use of a flux, which is a molten mixture of a solvent and a solute. The solute contains the crystal components, while the solvent dissolves the solute at high temperatures, allowing for crystal growth.

Flux growth is advantageous because it enables the production of high-quality BBO nonlinear crystals with controlled morphology, low defect density, and high purity. The flux can be optimized to control the crystal growth conditions, such as temperature, cooling rate, and composition, which affect the crystal quality. However, flux growth can be challenging to control, and the residual flux can contaminate the crystal, leading to reduced quality.

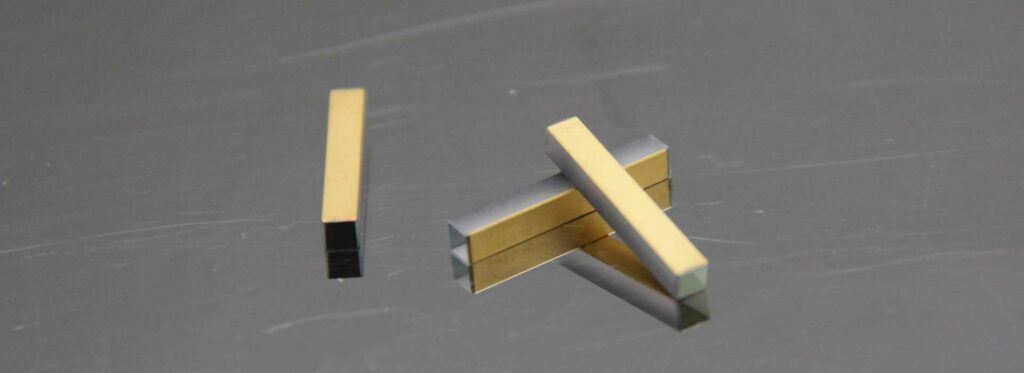

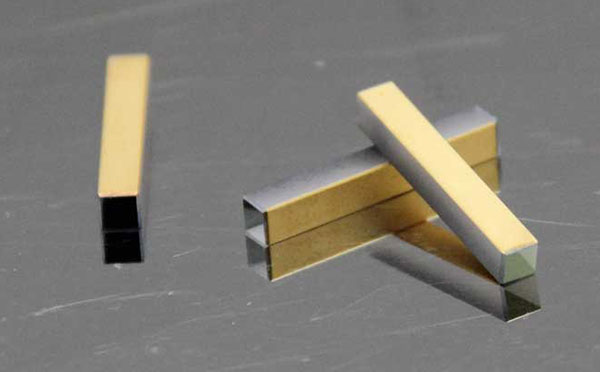

Polishing Techniques

The surface quality of BBO crystals is critical for achieving high conversion efficiency and low loss. The polishing technique used to fabricate BaB2O4 crystals plays a crucial role in determining their surface quality. The most common polishing techniques for BBO crystals include mechanical polishing, chemical-mechanical polishing, and ion-beam polishing. Mechanical polishing is a simple and cost-effective technique but can introduce surface defects and scratches. Chemical-mechanical polishing provides higher surface quality and is commonly used for fabricating high-quality BaB2O4 crystals. Ion-beam polishing is a more advanced technique that provides the highest surface quality but is more expensive.

Coating Techniques

BBO crystals are often coated with anti-reflection (AR) and high-reflection (HR) coatings to enhance their optical properties. AR coatings are used to minimize the reflection of incident light at the surface of the crystal, while HR coatings are used to maximize the reflection of light within the crystal. Coatings can be applied to BaB2O4 crystals using several techniques, including thermal evaporation, electron-beam evaporation, and sputtering. Thermal evaporation is the most commonly used technique due to its low cost and simplicity.

Quality Control Techniques

Quality control techniques are essential for ensuring the quality of BBO crystals. There are several quality control techniques available for BBO crystals, including X-ray diffraction, photoluminescence, and thermal imaging. X-ray diffraction is used to determine the crystal structure and quality of the BaB2O4 crystals. Photoluminescence is used to measure the purity and defect density of the crystal. Thermal imaging is used to detect defects and inhomogeneities in the crystal.

Conclusion

In conclusion, the quality of BBO crystals is critical for achieving high conversion efficiency, low loss, and a narrow spectral bandwidth in optoelectronic devices that use frequency doubling. Fabrication techniques, such as crystal growth, polishing, and coating, play a crucial role in determining the quality of BaB2O4 crystals. Quality control techniques, such as X-ray diffraction, photoluminescence, and thermal imaging, are also essential for ensuring the quality of BBO crystals. By using these techniques, high-quality BBO crystals can be fabricated for use in a wide range of optoelectronic applications.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article