1. Introduction to LBO Crystal Cleaning

1.1 Overview of LBO Crystals

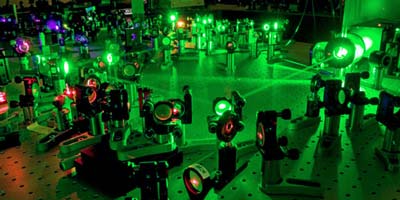

Lithium triborate (LBO) is a non-linear optical crystal that has been widely used in various optical instruments, including frequency doublers and triplers, optical parametric oscillators, and ultrafast lasers. The crystal has excellent transparency across a broad range of wavelengths, high laser-induced damage threshold, and relatively large non-linear coefficient, making it an attractive choice for many applications.

However, LBO crystals are susceptible to various types of contamination, which can significantly impact their performance. Contamination can occur in various forms, such as dust, fingerprints, water spots, or even oxidation, resulting in a decrease in output power and a reduction in efficiency. Therefore, proper clean and maintenance are essential to ensure that LBO crystals maintain optimal performance throughout their lifespan.

1.2 Importance of LBO Crystal Cleaning

The cleanliness of LBO crystals plays a critical role in the performance of optical instruments. Even minor contamination can lead to significant power losses and, in some cases, permanent damage to the crystal. For example, dust particles or fingerprints can scatter light and cause optical losses, while water spots can cause distortion or even crack the crystal under intense laser irradiation.

Contamination can also affect the quality of the beam produced by optical instruments, leading to reduced beam quality, reduced coherence, and increased divergence. Therefore, maintaining the cleanliness of LBO crystals is crucial to ensuring the stability and reliability of optical systems.

1.3 LBO Crystal Cleaning Techniques

LBO crystal clean can be challenging due to the crystal’s sensitivity to damage and the risk of introducing new contamination. The most common LBO crystal clean techniques include dry and wet cleaning methods.

Dry clean involves using an air duster or a soft brush to remove loose contaminants from the surface of the crystal. This method is suitable for removing dust or other dry contaminants that do not adhere to the surface. However, it is not effective against oily or sticky substances that require wet cleaning.

Wet clean involves using a solvent or a cleaning solution to dissolve or dislodge contaminants from the crystal surface. This method is more effective against oily or sticky substances, but it also carries a higher risk of introducing new contamination or damaging the crystal.

1.4 Equipment Required for LBO Crystal Cleaning

The equipment required for LBO crystal clean depends on the cleaning method used. For dry clean, an air duster or a soft brush is required to remove loose contaminants from the surface. For wet clean, the following equipment is typically required:

Cleaning solution: A clean solution is required to dissolve or dislodge contaminants from the crystal surface. The choice of clean solution depends on the type of contamination and the sensitivity of the crystal. Common clean solutions include isopropyl alcohol, acetone, and deionized water.

Cleaning cloth: A lint-free cleaning cloth is required to apply the cleaning solution to the crystal surface and remove the dissolved contaminants. Microfiber or cotton swabs are commonly used for this purpose.

Gloves: Gloves are required to avoid introducing new contaminants from the hands while handling the crystal or cleaning equipment.

Safety glasses: Safety glasses are required to protect the eyes from potential hazards during the cleaning process.

1.5 Risks of Improper Cleaning Techniques

Improper LBO crystal clean techniques can lead to permanent damage to the crystal or introduce new contaminants that can affect the crystal’s performance. Some of the risks associated with improper clean techniques include:

- Scratching or cracking the crystal surface: LBO crystals are relatively fragile and can be easily scratched or cracked if mishandled during the cleaning process.

- Introducing new contaminants: The cleaning equipment or the cleaning solution itself can introduce new contaminants to the crystal.

- Chemical reactions: Certain clean solutions can react with LBO crystals and cause damage or discoloration. For example, strong acids or alkalis can etch the crystal surface or remove its protective coatings.

- Altering crystal properties: Improper clean techniques can alter the crystal’s surface properties, such as its roughness, flatness, or optical quality, which can affect its performance.

- Incomplete cleaning: Incomplete clean can leave behind residues or contaminants that can affect the crystal’s performance, leading to reduced output power or increased optical losses.

1.6 Summary

In summary, maintaining the cleanliness of LBO crystals is crucial to ensuring the stability and reliability of optical instruments. Various contaminants can affect the crystal’s performance, leading to reduced output power, decreased efficiency, and altered beam properties. Therefore, proper LBO crystal cleaning techniques are necessary to remove contaminants and maintain optimal performance. The next chapter will discuss the different types of contamination that can affect LBO crystals and their impact on the crystal’s performance.

2. Understanding Optical Equipment Contamination

2.1 Types of Contamination

LBO crystals can be contaminated by various types of substances, such as dust, fingerprints, water spots, oils, and greases. Contaminants can be deposited on the crystal surface from the surrounding environment, the handling of the crystal, or the clean process. The following sections describe the different types of contamination and their impact on the crystal’s performance.

2.1.1 Dust and Particles

Dust and particles are common contaminants that can accumulate on LBO crystals and cause optical losses. These contaminants can scatter light, reducing the crystal’s transmittance and reflectance, and lead to reduced output power. Dust and particles can also scratch the crystal surface, leading to increased scatter and further reducing its optical properties.

2.1.2 Fingerprints

Fingerprints are oily residues left behind by skin oils, sweat, or other contaminants on the crystal surface. These residues can cause optical losses by scattering light, reducing the crystal’s transmittance, and altering its refractive index. Fingerprints can also leave behind residues that attract dust and particles, leading to further contamination.

2.1.3 Water Spots

Water spots are a common form of contamination caused by water droplets that have evaporated from the crystal surface, leaving behind mineral deposits or other residues. Water spots can cause optical distortions, leading to increased scatter and reduced beam quality. In some cases, water spots can also lead to the formation of microcracks in the crystal surface, leading to reduced crystal lifetime.

2.1.4 Oils and Greases

Oils and greases are common contaminants that can accumulate on LBO crystals and cause significant optical losses. These contaminants can scatter light, reduce the crystal’s transmittance, and alter its refractive index. Oils and greases can also attract dust and particles, leading to further contamination.

2.2 Sources of Contamination

Contamination can be introduced to LBO crystals from various sources, such as the surrounding environment, the handling of the crystal, or the clean process. The following sections describe the different sources of contamination and their impact on the crystal’s performance.

2.2.1 Environment

The surrounding environment can be a significant source of contamination for LBO crystals. Contaminants such as dust, particles, and water droplets can be present in the air or on surfaces and can easily deposit on the crystal surface. Contamination can be exacerbated by high humidity or temperature conditions, which can increase the adhesion of particles to the crystal surface.

2.2.2 Handling

Handling LBO crystals can introduce contaminants from the skin, such as oils and sweat, or from the handling equipment, such as dust or particles. Improper handling techniques can also scratch or crack the crystal surface, leading to further contamination or permanent damage.

2.2.3 Cleaning

Improper cleaning techniques can introduce new contaminants or damage the crystal surface, leading to reduced optical properties. Clean equipment or cleaning solutions can also leave behind residues that attract dust and particles, leading to further contamination.

2.3 Impact of Contamination on Optical Properties

Contamination can significantly impact the performance of LBO crystals, leading to reduced output power, decreased efficiency, altered beam properties, and reduced crystal lifetime. The following sections describe the impact of contamination on different optical properties.

2.3.1 Transmittance and Reflectance

Contaminants can scatter light and reduce the crystal’s transmittance and reflectance, leading to reduced output power and increased optical losses. The amount of light scattered depends on the size, shape, and refractive index of the contaminant.

2.3.2 Refractive Index

Contaminants can alter the refractive index of the crystal, leading to changes in the beam’s path or divergence. This can cause distortions in the beam profile, leading to reduced beam quality and coherence. The extent of the refractive index change depends on the type and amount of the contaminant and its location on the crystal surface.

2.3.3 Surface Roughness

Contaminants can also alter the surface roughness of the crystal, leading to increased scatter and reduced optical properties. Even minor scratches or cracks on the crystal surface can cause significant scatter, leading to reduced beam quality and output power.

2.3.4 Crystal Lifetime

Contamination can also impact the crystal’s lifetime by introducing defects or causing surface damage that can lead to cracking or other forms of permanent damage. For example, water spots can lead to the formation of microcracks, which can grow under laser irradiation, leading to reduced crystal lifetime.

2.4 Summary

In summary, LBO crystals can be contaminated by various types of substances, including dust, fingerprints, water spots, oils, and greases. Contamination can be introduced from the surrounding environment, handling of the crystal, or the cleaning process. Contamination can significantly impact the crystal’s performance, leading to reduced output power, decreased efficiency, altered beam properties, and reduced crystal lifetime. Therefore, it is essential to understand the different types of contamination and their impact on the crystal’s optical properties to choose the appropriate clean method and maintain optimal performance. The next chapter will discuss the preparation steps required before cleaning LBO crystals to ensure the best possible results.

3. Preparing for LBO Crystal Clean

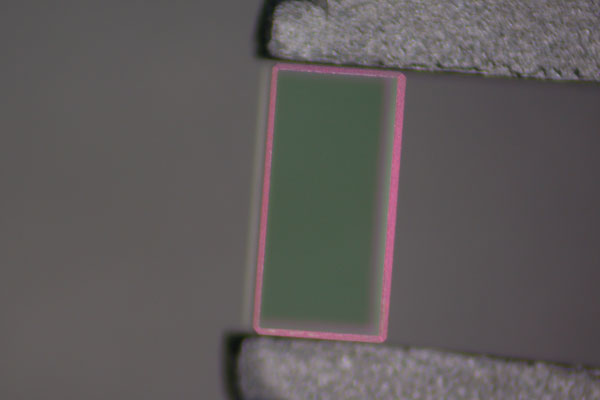

3.1 Pre-Cleaning Inspection

Before starting the cleaning process, it is crucial to inspect the LBO crystal for any signs of damage or defects. Any cracks, scratches, or other surface defects can exacerbate contamination and reduce the crystal’s performance. Therefore, it is essential to address any surface damage before proceeding with the cleaning process.

Inspecting the crystal also allows the user to identify the type and location of the contamination, which can affect the choice of cleaning method and the equipment required.

3.2 Cleaning Area Preparation

The clean area should be prepared to minimize the risk of introducing new contamination to the crystal during the cleaning process. The following steps can be taken to prepare the cleaning area:

- Clean the work surface: The work surface should be cleaned with a lint-free cloth or paper towel to remove any dust or particles that may have accumulated.

- Use an air purifier: An air purifier can help remove airborne contaminants, such as dust or particles, from the cleaning area.

- Minimize foot traffic: The clean area should be isolated from foot traffic to reduce the risk of introducing new contamination.

- Wear cleanroom attire: Cleanroom attire, including a cleanroom suit, hairnet, and shoe covers, can help minimize the introduction of new contaminants to the cleaning area.

3.3 Equipment Preparation

The following equipment should be prepared before starting the cleaning process:

- Cleaning solution: The appropriate cleaning solution should be selected based on the type and location of the contamination. Isopropyl alcohol, acetone, and deionized water are commonly used cleaning solutions for LBO crystals.

- Cleaning cloth: A lint-free clean cloth or microfiber cloth should be used to apply the cleaning solution and remove dissolved contaminants from the crystal surface.

- Cleaning tools: Specialized clean tools, such as brushes or swabs, may be required to remove contaminants from hard-to-reach areas.

- Gloves: Cleanroom gloves should be worn to avoid introducing new contaminants from the hands during the cleaning process.

- Safety glasses: Safety glasses should be worn to protect the eyes from potential hazards during the cleaning process.

3.4 Cleaning Method Selection

The choice of cleaning method depends on the type and location of the contamination and the crystal’s sensitivity to damage. Dry cleaning is suitable for removing loose contaminants, such as dust or particles, from the crystal surface. Wet cleaning is required for more stubborn contaminants, such as fingerprints or oils, that require solvents or cleaning solutions to dissolve or dislodge.

The user should also consider the crystal’s sensitivity to damage when selecting the clean method. Dry cleaning methods, such as air dusters or soft brushes, are less likely to damage the crystal surface than wet cleaning methods, which can carry a higher risk of introducing new contamination or damaging the crystal.

3.5 Summary

In summary, preparing for LBO crystal clean is an essential step in maintaining optimal performance and minimizing the risk of introducing new contamination. Pre-cleaning inspection allows the user to identify any surface defects or contamination and choose the appropriate cleaning method. The cleaning area should be prepared to minimize the introduction of new contamination, and the required equipment and cleaning solutions should be selected and prepared before starting the cleaning process. The next chapter will discuss the different techniques used to clean LBO crystals, including dry and wet cleaning methods.

4. Dry Cleaning Techniques for LBO Crystals

4.1 Air Duster

Air dusters are commonly used to remove loose contaminants, such as dust or particles, from the surface of LBO crystals. Air dusters use compressed air to blow away loose contaminants without the need for physical contact with the crystal surface. Air dusters can be purchased from most electronics or computer supply stores.

To use an air duster, the following steps should be taken:

- Hold the air duster can upright and direct the nozzle towards the crystal surface.

- Spray short bursts of air onto the crystal surface, moving the nozzle in a back-and-forth motion.

- Repeat the process until all loose contaminants are removed from the crystal surface.

- Air dusters are suitable for removing dry contaminants that do not adhere to the surface of the crystal. However, they are not effective against oily or sticky substances that require wet cleaning.

4.2 Soft Brush

Soft brushes are also commonly used to remove loose contaminants from the surface of LBO crystals. Soft brushes are gentle enough not to scratch or damage the crystal surface and can be purchased from most camera or optical supply stores.

To use a soft brush, the following steps should be taken:

- Gently brush the crystal surface in a back-and-forth motion, starting from the top of the crystal and working downwards.

- Use a dustpan or a lint-free cloth to collect any loose contaminants that have been removed from the crystal surface.

- Repeat the process until all loose contaminants are removed from the crystal surface.

- Soft brushes are suitable for removing dry contaminants, such as dust or particles, that do not adhere strongly to the crystal surface. However, they may not be effective against oily or sticky substances that require wet clean.

4.3 Summary

Dry clean techniques, such as air dusters and soft brushes, are suitable for removing loose contaminants from the surface of LBO crystals. Air dusters use compressed air to blow away dry contaminants without the need for physical contact with the crystal surface, while soft brushes gently brush away loose contaminants without damaging the crystal surface. However, dry cleaning techniques may not be effective against oily or sticky substances that require wet cleaning. The next chapter will discuss wet cleaning techniques for LBO crystals, including the different types of cleaning solutions and the appropriate cleaning procedures.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article