The last article provides an overview of Lithium triborate (LBO) crystals, a type of non-linear optical crystal used in various optical instruments. It highlights the susceptibility of these crystals to contamination, such as dust, fingerprints, water spots, and oxidation, which can reduce their output power and efficiency. As such, proper cleaning and maintenance are necessary to maintain optimal performance.

The last article also details different cleaning techniques for LBO crystals, including dry and wet cleaning methods, and outlines the equipment required for each method. Furthermore, it discusses the risks associated with improper cleaning techniques, which can lead to permanent damage or the introduction of new contaminants. The last article then covers the types of contamination that can affect LBO crystals, their sources, and their impact on the crystal’s performance. This article picks up where the previous article left off.

5. Wet Cleaning Techniques for LBO Crystals

5.1 Cleaning Solutions

Wet cleaning techniques use cleaning solutions or solvents to dissolve or dislodge stubborn contaminants, such as fingerprints or oils, from the surface of LBO crystals. The choice of cleaning solution depends on the type and location of the contamination and the crystal’s sensitivity to damage.

The following are common cleaning solutions used for LBO crystals:

- Isopropyl alcohol: Isopropyl alcohol is a commonly used cleaning solution for LBO crystals. It is effective in removing oils and other organic contaminants from the crystal surface.

- Acetone: Acetone is another commonly used cleaning solution for LBO crystals. It is effective in removing oils, greases, and other organic contaminants from the crystal surface.

- Deionized water: Deionized water is a non-polar cleaning solution that is effective in removing inorganic contaminants, such as salts or minerals, from the crystal surface.

It is important to note that certain cleaning solutions can react with LBO crystals and cause damage or discoloration. Therefore, it is essential to select the appropriate cleaning solution based on the type and location of the contamination and the crystal’s sensitivity to damage.

5.2 Cleaning Procedure

The following steps should be taken when using wet cleaning techniques to clean LBO crystals:

- Apply the cleaning solution: Apply the appropriate cleaning solution to a lint-free cleaning cloth or microfiber cloth.

- Gently wipe the crystal surface: Gently wipe the crystal surface in a back-and-forth motion, starting from the top of the crystal and working downwards. Use a light pressure to avoid damaging the crystal surface.

- Repeat the process: Repeat the process until all contaminants are removed from the crystal surface.

- Rinse with deionized water: Rinse the crystal surface with deionized water to remove any residue from the cleaning solution.

- Dry the crystal: Dry the crystal surface using a lint-free cleaning cloth or air duster. Do not use heat to dry the crystal, as it can damage the crystal surface.

It is important to note that wet cleaning techniques may not be suitable for all types of contamination, and the crystal’s sensitivity to damage should be considered when selecting the appropriate cleaning method.

5.3 Ultrasonic Cleaning

Ultrasonic cleaning is another wet cleaning technique that uses high-frequency sound waves to remove contaminants from the surface of LBO crystals. Ultrasonic cleaning is effective in removing stubborn contaminants, such as oils or greases, from the crystal surface and can be performed using a specialized ultrasonic cleaning machine.

To perform ultrasonic cleaning, the following steps should be taken:

- Fill the ultrasonic cleaning tank with the appropriate cleaning solution.

- Place the LBO crystal in the cleaning tank, ensuring that it is completely submerged.

- Turn on the ultrasonic cleaning machine and set the frequency and cleaning time based on the type and location of the contamination.

- After the cleaning cycle is complete, rinse the crystal surface with deionized water and dry using a lint-free cleaning cloth or air duster.

It is important to note that ultrasonic cleaning can be more aggressive than other cleaning methods and should be used with caution to avoid damaging the crystal surface.

5.4 Summary

Wet cleaning techniques, such as using cleaning solutions or ultrasonic cleaning, are effective in removing stubborn contaminants, such as oils or greases, from the surface of LBO crystals. The choice of cleaning solution depends on the type and location of the contamination and the crystal’s sensitivity to damage. The cleaning procedure should be performed carefully to avoid damaging the crystal surface, and ultrasonic cleaning should be used with caution to avoid excessive cleaning. The next chapter will discuss

6. Post-Cleaning Inspection and Quality Control

6.1 Post-Cleaning Inspection

After cleaning an LBO crystal, it is important to perform a post-cleaning inspection to ensure that all contaminants have been removed from the crystal surface and that the cleaning process has not caused any damage to the crystal.

The following steps should be taken during post-cleaning inspection:

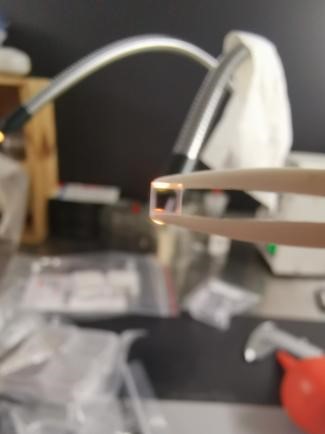

- Inspect the crystal surface: Examine the crystal surface under a magnifying glass or microscope to check for any remaining contaminants or surface damage.

- Check the crystal properties: Measure the crystal’s optical properties, such as transmission or refractive index, to ensure that the cleaning process has not affected the crystal’s performance.

- Test the crystal: Test the crystal’s performance, such as its output power or beam profile, to ensure that it is functioning correctly.

If any issues are identified during post-cleaning inspection, the cleaning process should be repeated, or additional steps should be taken to address the issue.

6.2 Quality Control

Quality control measures should be implemented to ensure consistent cleaning results and minimize the risk of introducing new contamination. The following are common quality control measures for LBO crystal cleaning:

- Cleaning procedure documentation: The cleaning procedure should be documented to ensure that the same cleaning process is used consistently and to track any changes or modifications made to the cleaning process.

- Regular cleaning intervals: Regular cleaning intervals should be established to ensure that the crystal is cleaned before contamination buildup can affect its performance.

- Contamination source identification: The source of contamination should be identified and addressed to prevent recontamination after cleaning.

- Environmental controls: Environmental controls, such as air purifiers or cleanroom attire, should be used to minimize the risk of introducing new contamination during the cleaning process.

- Performance testing: The crystal’s performance should be tested regularly to ensure that it is functioning correctly and to identify any issues before they affect the crystal’s performance.

By implementing quality control measures, the risk of introducing new contamination and damaging the crystal during cleaning can be minimized, and consistent cleaning results can be achieved.

6.3 Summary

Post-cleaning inspection and quality control are essential steps in ensuring that LBO crystals are cleaned effectively and that their performance is maintained. Post-cleaning inspection allows any remaining contamination or surface damage to be identified and addressed, while quality control measures ensure consistent cleaning results and minimize the risk of introducing new contamination. The next chapter will discuss common mistakes and issues that can occur during LBO crystal cleaning and how to avoid them.

7. Common Mistakes and Issues in LBO Crystal Cleaning

Cleaning LBO crystals requires care and attention to detail to avoid damaging the crystal surface or introducing new contamination. The following are common mistakes and issues that can occur during LBO crystal cleaning and how to avoid them.

7.1 Using the Wrong Cleaning Solution

Using the wrong cleaning solution can damage the crystal surface or cause discoloration. Before cleaning an LBO crystal, it is essential to identify the type and location of the contamination and select the appropriate cleaning solution based on the crystal’s sensitivity to damage.

To avoid using the wrong cleaning solution, it is important to:

- Identify the type and location of the contamination

- Research the appropriate cleaning solutions for the type of contamination

- Test the cleaning solution on a small area of the crystal surface to ensure that it does not cause damage or discoloration.

7.2 Using the Wrong Cleaning Procedure

Using the wrong cleaning procedure can damage the crystal surface or leave behind contaminants. The cleaning procedure should be selected based on the type and location of the contamination and the crystal’s sensitivity to damage.

To avoid using the wrong cleaning procedure, it is important to:

- Identify the type and location of the contamination

- Research the appropriate cleaning procedure for the type of contamination

- Follow the cleaning procedure carefully and avoid using excessive force or pressure.

7.3 Introducing New Contamination

Introducing new contamination during the cleaning process can negate the benefits of cleaning and reduce the crystal’s performance. New contamination can be introduced through air currents, dust or particles, or contact with contaminated surfaces or equipment.

To avoid introducing new contamination, it is important to:

- Prepare the cleaning area by cleaning the work surface and using an air purifier

- Minimize foot traffic in the cleaning area

- Wear cleanroom attire to minimize the introduction of new contaminants from the body

- Use clean equipment and cleanroom gloves to avoid introducing new contaminants from the hands

7.4 Over-Cleaning

Over-cleaning the crystal surface can cause damage or affect the crystal’s performance. Over-cleaning can result from using the wrong cleaning solution, using excessive force or pressure, or cleaning the crystal too frequently.

To avoid over-cleaning, it is important to:

- Follow the recommended cleaning intervals to avoid cleaning the crystal too frequently

- Use the appropriate cleaning solution and procedure for the type of contamination

- Avoid using excessive force or pressure during cleaning

- Test the crystal’s performance after cleaning to ensure that it has not been affected.

7.5 Summary

Cleaning LBO crystals requires care and attention to detail to avoid damaging the crystal surface or introducing new contamination. Common mistakes and issues, such as using the wrong cleaning solution or procedure, introducing new contamination, or over-cleaning the crystal surface, can affect the crystal’s performance. By identifying and avoiding these issues, the cleaning process can be performed effectively, and the crystal’s performance can be maintained. The final chapter will summarize the key points of LBO crystal cleaning and provide tips for effective cleaning.

8. Summary and Tips for Effective LBO Crystal Cleaning

Cleaning LBO crystals is an essential task to maintain their performance and ensure their longevity. Effective cleaning requires attention to detail and careful selection of cleaning solutions and procedures. This chapter will summarize the key points of LBO crystal cleaning and provide tips for effective cleaning.

8.1 Key Points

The following are key points to consider when cleaning LBO crystals:

- Identify the type and location of the contamination

- Select the appropriate cleaning solution and procedure based on the type and location of the contamination and the crystal’s sensitivity to damage

- Avoid using excessive force or pressure during cleaning

- Minimize the introduction of new contamination by preparing the cleaning area, using cleanroom attire, and using clean equipment

- Perform post-cleaning inspection and quality control to ensure consistent cleaning results and maintain the crystal’s performance.

By following these key points, LBO crystals can be effectively cleaned, and their performance can be maintained.

8.2 Tips for Effective Cleaning

The following are tips for effective cleaning of LBO crystals:

- Use a lint-free cleaning cloth or microfiber cloth to avoid leaving behind fibers or particles on the crystal surface.

- Use deionized water to rinse the crystal surface to avoid introducing new contamination from tap water.

- Perform cleaning in a laminar flow hood or cleanroom to minimize the introduction of new contamination.

- Use a magnifying glass or microscope to inspect the crystal surface after cleaning to ensure that all contaminants have been removed.

- Test the crystal’s performance after cleaning to ensure that it has not been affected.

- Document the cleaning procedure and perform regular cleaning intervals to ensure consistent cleaning results and maintain the crystal’s performance.

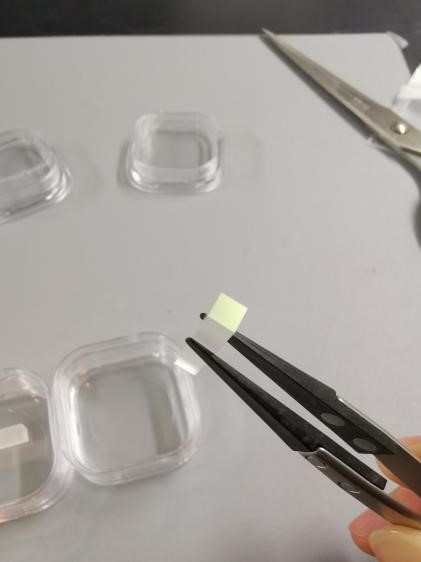

- Handle the crystal with cleanroom gloves or tweezers to avoid introducing new contamination from the hands.

By following these tips, LBO crystals can be effectively cleaned and their performance can be maintained over time.

8.3 Conclusion

Cleaning LBO crystals is an essential task to maintain their performance and ensure their longevity. Effective cleaning requires attention to detail and careful selection of cleaning solutions and procedures. By following the key points and tips outlined in this guide, LBO crystals can be effectively cleaned, and their performance can be maintained over time.

Frank

Frank graduated from the University of Shanghai for Science and Technology, majoring in optics. As a technical engineer at Crylink Company, he deeply understands crystal materials and laser components.

Related Video(s) with this Article

Related Product(s) with this Article

Related Application(s) with this Article